In the industry, improving production processes and increasing efficiency are among the most important tasks on the daily to-do list. This applies to the process of making the parts or goods themselves, as well as to their quality control, record keeping and, of course, the organization of the production process.

Optimising even a small part of the production process can bring significant benefits in the long term and provide a good information base for further decision-making.

In this article, we will look at how motion control products can improve work organisation and provide the necessary information.

Table of contents:

In industrial production, automation systems can be complex, forming complex networks of interconnected subsystems, but the most important moments in any system are the beginning and the end. Knowing the key reference points, the start and end of the system, allows measurements to be made within the system. What measurements to make? Here are some examples:

If you do not already have automatic production accounting in place, there are a number of ways to do this, from a relatively simple solution (receiver + counter) to more sophisticated data exchange and analysis solutions.

More and more companies are implementing quality control solutions directly in the production equipment and/or production lines in order to detect and report sub-standard production as quickly as possible, thus reducing the quantity of low-quality production and the material, energy and time resources consumed. Depending on the nature of the product and the defects to be expected, we will select the most appropriate quality control tools. These may be, for example, capacitive sensors that detect the movement of an empty (non-filled with liquid) plastic bottle along the production line, photo sensors that monitor the colour consistency of the product or smart vision solutions that can identify "anomalies" in the appearance of the product with the help of artificial intelligence.

More and more companies are implementing quality control solutions directly in the production equipment and/or production lines in order to detect and report sub-standard production as quickly as possible, thus reducing the quantity of low-quality production and the material, energy and time resources consumed. Depending on the nature of the product and the defects to be expected, we will select the most appropriate quality control tools. These may be, for example, capacitive sensors that detect the movement of an empty (non-filled with liquid) plastic bottle along the production line, photo sensors that monitor the colour consistency of the product or smart vision solutions that can identify "anomalies" in the appearance of the product with the help of artificial intelligence.

Reducing waste is essential for every operator, but before doing so, it must be identified. Automated solutions make it relatively easy to report on how much of the incoming raw material is used in the finished product and what the level of wastage is. Based on this type of data, changes to raw material specifications can be planned more transparently to minimise wastage and maximise resource efficiency.

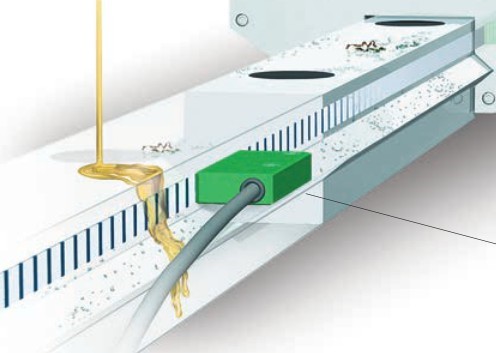

There are bound to be points in the production flow where raw materials are fed, and to monitor the availability of the required materials at these points, bunkers in the feeding equipment can be equipped with sensors that will signal the need for restocking at a certain level. These may be, for example, a level control in the glue hopper, a control of the end of the paper roll diamater drop/stop, a control of the temper, pressure or other process that will signal when it is time to replenish or replace the raw material.

Just as important as measuring and controlling the above physical parameters is the analysis of the time taken to produce the product. Time is money and in a manufacturing business the amount of output produced in time is one of the most important indicators. By implementing control tools and integrating them into the production system, data can be generated to analyse the dynamics of the production process - when production speeds were higher, when they were lower, how long the downtimes were, what the maximum production speeds were, which production stages are experiencing bottlenecks, how to adjust the speeds of the different lines, etc.

SIA "Lāsma" has over 30 years of experience in hundreds of different solutions implemented in the manufacturing industry, each of which, although sometimes conceptually similar, is differently tailored.

Choosing less well-known manufacturers and sourcing from third markets may save you a few tens or hundreds of euros, but the risks of maintenance and replacement can cost many times more.

|

|

|

|

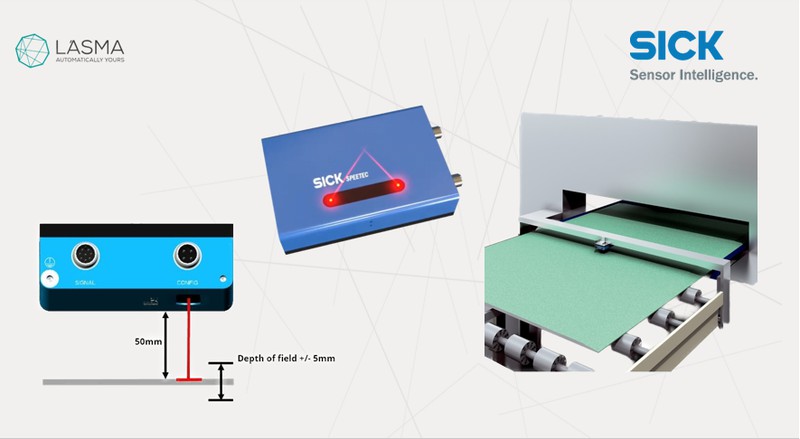

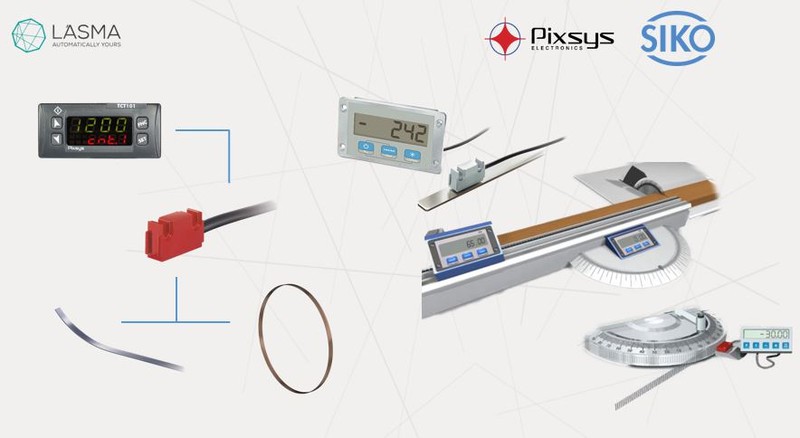

| Non-contact speed and length measurement of plasterboards | Position and quality control | Non-contact linear and angular displacement measurement | Displacement meter |

Tell us about your idea - we'll offer the right solution to automate your production process.