Time is passing, and the manufacturing industry is rapidly evolving in many aspects, with one of them being automation systems. Company leaders continue to seek effective solutions to improve manufacturing processes, increase output, and reduce costs. The physical workload of human resources is gradually decreasing as machines and robots replace more challenging tasks. Recently, we informed you about the servo control system from Trio Motion Technology servo control system from Trio Motion Technology, which efficiently automates equipment operations. This time, we want to tell you about another valuable product from this manufacturer. It is the fast and powerful motion controller Flex-6 Nano, specifically designed for optimal servo motor performance.

Table of Contents

A motion controller is a device that guides or determines the operation of a servo motor. This controller dictates the action of an automatic control system, which is carried out according to a predefined scheme. For example, an object can be pulled, lifted, lowered, rotated, or stopped, etc.

These motion controllers, in connection with servo motors, have a very wide range of applications. Servo motors themselves can be used starting from toys, home electronics, and up to complex manufacturing automation processes. They are particularly suitable for use in the packaging, printing, textile, and assembly industries. In industry, servo motors are used not only to replace conventional AC and stepper motors but also as an innovative solution for conveyor belts and manufacturing equipment. Applications are also found in hydraulic and pneumatic systems.

Flex-6 Nano is a powerful, high-speed, and compact motion controller. It can be installed in a control cabinet on a DIN rail. The small dimensions of the device make it very compact. Flex-6 Nano has built-in 1 GB DDR3 memory, which can be expanded up to 32 GB using a Micro SD card if needed.

This motion controller from Trio Motion Technology allows the control of up to 128 servo or stepper motors with digital I/O and additional equipment, such as human-machine interfaces (HMI). All of this is controlled from a single source. The system can use an autonomous program, or commands can be sent from an external device (computer).

| Factory model | Axis | Individually designed set |

| P600 | 2 | P600 |

| P601 | 4 | P600 + 1 x P912 |

| P602 | 8 | P600 + 2 x P912 |

| P603 | 16 | P600 + 3 x P912 |

| P604 | 32 | P600 + 4 x P912 |

| P605 | 64 | P600 + 5 x P912 |

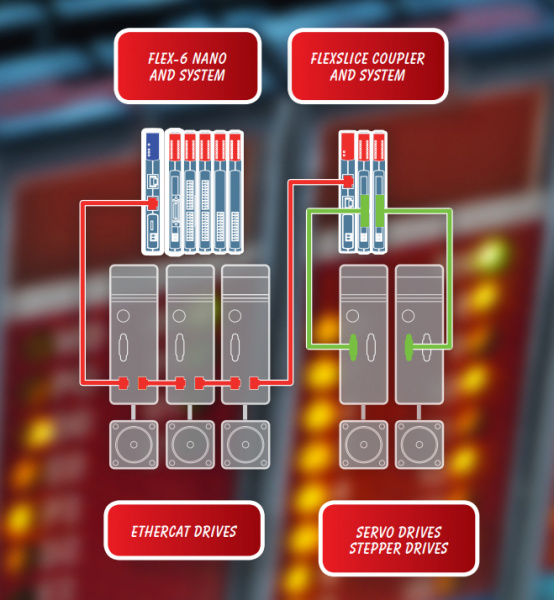

The Flex-6 Nano EtherCAT can be used as a standalone device or connected to the Trio EtherCAT Flexslice system.

The EtherCAT Flexslice system is designed to empower any engineer to achieve more. It offers fast and flexible expansion for applications of varying complexity.

In addition to synchronous control with the EtherCAT protocol, the system can be expanded to control drive command pulses, direction, binary, analog I/O, and other functionalities that comply with the EtherCAT standard.

Multiple "stations" or EtherCAT-connected Flexslice module blocks can be added to the network. They can be connected using the P600 second EtherCAT port to establish a connection with one or more P366 Flexslice connectors.

Below, we present 9 Flexslice modules designed for larger workloads:

P366 Flexslice Coupler – This module starts with a connector connected to the network using the upper Ethernet interface. The lower RJ45 socket can be used to connect other EtherCAT devices on the same chain.

P371 Flexslice 16-Out PNP – This module connects binary control signals from the Motion Coordinator to machine output devices at 24 V DC.

P372 Flexslice 16-In PNP – The digital input section of this module connects 24 V DC signals from machine devices with binary control registers in the Motion Coordinator.

P362 Flexslice Power Connect – This module simplifies the connection to the I/O system. Quick and easy installation due to easy wire connection, thanks to the push-fit connection.

P367 Flexslice Thermocouple – This module has 4 thermocouple inputs, each with 16-bit resolution, providing flexibility to meet various temperature measurement needs.

P372 Flexslice Analogue 2 Servo Axes – A model with a 16-inch PNP. This model connects 24 V DC signals from machine devices with binary control registers in the Motion Coordinator.

P375 Flexslice Flex 3-Axis – This module controls up to 3-axis motors with pulse/direction/enable or pulse/direction/registration signals for each axis.

P378 Flexslice 8 Analogue Outputs – This module has eight programmable voltage range outputs, each with 12-bit resolution.

P379 Flexslice 8 Analogue Inputs – This module has eight programmable voltage range inputs, each with 12-bit resolution.