Nowdays, topics related to energy resource conservation and production optimization are becoming increasingly relevant. This perspective is not only ours but also that of our customers. Some of the questions we receive from our customers include: How to optimize a specific production process? How to improve the efficiency of Servo motors? How to select/connect a servo driver? In this article, we will attempt to answer these questions and introduce the new DX3 servo driver, which is an integral part of the servo motor control system. It's important to remember that this driver expands the capabilities of production equipment and saves you time.

The topics we will cover:

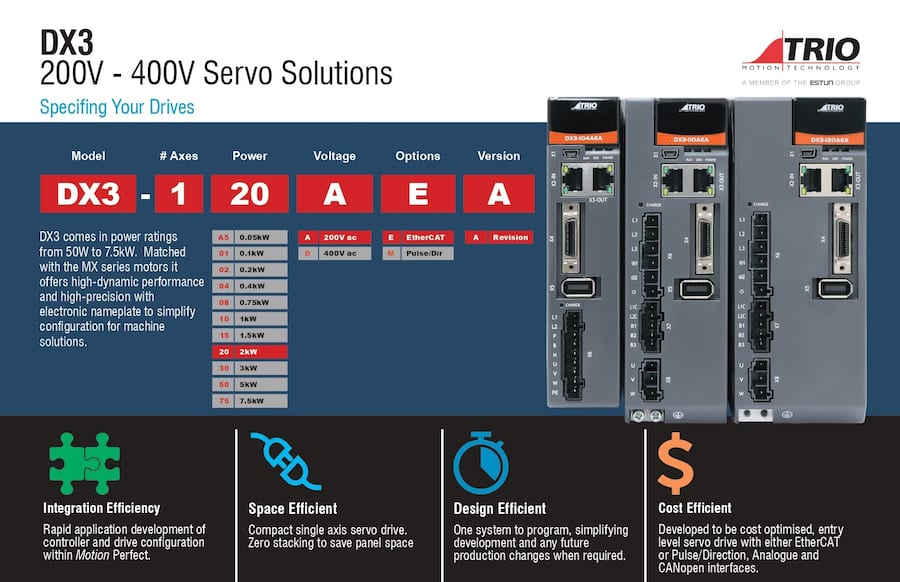

DX3 is a one-axis servo driver from Trio Motion Technology, a unique solution for controlling a single servo motor across a wide range. The DX3 servo driver is designed to provide an efficient and optimal input data solution with high performance and practical control features.

It's worth noting that the new DX3 servo drive model is compatible with the MXL and MXM series servo motors, which we discussed in one of our previous articles. This model is also compatible with Trio Motion controllers. The DX3 servo driver was created to deliver rapid control data transmission, high precision, and performance. Thanks to these features, many manufacturers choose the DX3 servo driver.

Due to its wide range of applications, DX3 servo driver models are available with power ratings range from 50W to 7.5kW. Various communication options are also available, such as EtherCAT, pulse, direction, analog, and CANopen. They can be selected as needed according to the project requirements

Surprisingly, servo drivers are so widely used in equipment that we may not even be aware of their presence. Systems interacting with servo drives occur literally every day, for example: cameras, telescopes, antennas, elevators, and much more. Servo drivers are primarily used in industrial manufacturing to automate equipment and reduce the potential for human errors. Their applications are highly diverse, ranging from material handling over short distances to robotic cargo movement. Undoubtedly, their use can enhance workplace safety, especially in hazardous conditions. Below are many more areas in which servo drivers are used in:

In other words, it's all equipment that unquestionably enhances productivity and production volumes.

Practically, in any manufacturing facility, there are devices that incorporate servo motors. Our observations show that users often don't know how to correctly connect a servo driver. The new DX3 servo driver, starting in 2023, is fully integrated into the Motion Perfect software. With it, everyone can find the right tool for connecting, planning, configuring, visualizing, and programming the system.

Connecting and configuring the DX3 servo driver is a relatively complex process, as evidenced by the extensive user manual provided by the manufacturer spanning hundreds of pages. During this work, numerous technical details must be taken into account, which are fundamental to the precise operation of the servo motor. To facilitate this work, in the following articles we will prepare detailed information on how to connect the servo drive driver more conveniently and correctly, in which we will cover the following topics: