The control and proper use of heating elements is a hot topic in manufacturing and households. We have found an effective solution for precise control of heating elements to ensure that electricity is used efficiently. In this article, we will explain how to achieve energy-efficient heating element control with Eurotherm EPACK LITE.

To start with, there are different variations of heating elements. Such as finger, flexible, sinking, circulating, air, temperature and other heating elements that are widely used for temperature control. There are also those designed for immersion in liquids to hold the liquid at a specific temperature. These heating elements can be used for applications ranging from freezing gutters to heating tanker cargo. There are also heating elements that can be attached to regular or irregularly shaped surfaces. In turn, they are widely used for frost protection. Whatever the purpose of the heating element, they all need to be monitored to ensure that they work accurately and energy efficiently.

As a real example here in Latvia, we can mention the introduction of heating element control at MB Holding. The main task of this project was to solve the control of heating elements and data transfer in two fire tanks depending on the water level. In this project, the heating element control systems offered by ZTF Lāsma were used.

Whether replacing an existing product or creating a new process, the EPack Lite SCR (Silicon Controlled Rectifier) power controller has been carefully designed to support easy and fast integration into industrial systems.Whether replacing an existing product or creating a new process, the EPack Lite SCR (Silicon Controlled Rectifier) power controller has been carefully designed to support easy and fast integration into industrial systems.

Whether replacing an existing product or creating a new process, the EPack Lite SCR (Silicon Controlled Rectifier) power controller has been carefully designed to support easy and fast integration into industrial systems.Whether replacing an existing product or creating a new process, the EPack Lite SCR (Silicon Controlled Rectifier) power controller has been carefully designed to support easy and fast integration into industrial systems.

The EPack Lite range of controllers offers a simplified choice to ensure a high level of quality, accuracy and reliability for your process. Definitively more than just a product, EPack Lite power controllers offer a professionally designed solution based on more than 50 years of Eurotherm experience worldwide.

EPACK LITE is available in 3 types, depending on the required project solution. Choose one of them. For easier transparency, we have created a table, see below.

| EPack Lite-1PH | EPack Lite-2PH | EPack Lite-3PH |

| 1-phase | 2-phase | 3-phase |

|

16 A, 25 A, 32 A, 40 A, 63 A, 80 A, 100 A, 125 A |

16 A, 25 A, 32 A, 40 A, 63 A, 80 A, 100 A, 125 A |

16 A, 25 A, 32 A, 40 A, 63 A, 80 A, 100 A, 125 A |

This EPack Lite-1PH controller provides single-phase constant impedance or primary transformer load control. It combines simplicity of set-up and operation in a compact format.

The EPack Lite-2PH is a latest generation power controller designed to be a cost-effective solution for controlling 3-phase loads, the control is specifically tailored to control balanced loads.

The EPack Lite-3PH controller is the ideal solution for constant resistance or primary transformer load control. Controlling each phase ensures precise control even when loads are unbalanced. Current and voltage measurements also ensure a high level of accuracy.

We've prepared an illustrative example of one of the principles of heating element control. In the video you will see how the Eurotherm EPack Lite roller controller works in combination with the Pixsys controller. This time we have chosen a luminaire with a resistive load as the test component - in this case it will be a spotlight.

For this example, we have chosen an EPackLite controller with 1 phase and 25 A output and a Pixsys controller with 4-20 mA output and PID control.

The quality of any product depends on choosing the right temperature and maintaining it correctly. Watlow Eurotherm has developed an effective solution for temperature control. The Eurotherm Epack provides unlimited possibilities to control production processes via several industrial communication protocols. The manufacturer offers the possibility to use EtherCAT, EtherNet/IP, Modbus TCP and ProfiNet protocols in its products to facilitate and optimise our work.The quality of any product depends on choosing the right temperature and maintaining it correctly.

Watlow Eurotherm has developed an effective solution for temperature control. The Eurotherm Epack provides unlimited possibilities to control production processes via several industrial communication protocols. The manufacturer offers the possibility to use EtherCAT, EtherNet/IP, Modbus TCP and ProfiNet protocols in its products to facilitate and optimise our work.

The implementation of Watlow Eurotherm products in production processes is quite complex and complicated, as certain parameters have to be controlled and checked. We recommend to facilitate this process by using Eurotherm iTools v9.86 software or one of the well-known equipment such as PLC or HMI visualisation panels.

Eurotherm iTools is a versatile suite of software tools that allows you to configure and monitor multiple controllers and relays. It also provides monitoring of the 6000 series graphic loggers. It can edit, save and "clone" complete controller configurations, as well as set up data logging, process monitoring and Ethernet and modem connections. In short, Eurotherm iTools performs the following processes:

Various controllers, data visualisation panels (HMI) and programmable logic controllers (PLC) can also be used to monitor certain parameters. As our company specialises in industrial automation products and solutions, we offer products from manufacturers such as:

Eurotherm joins US-based Watlow in 2023, becoming part of the experienced industrial giant. Eurotherm joins US-based Watlow in 2023, becoming part of the experienced industrial giant.

Eurotherm joins US-based Watlow in 2023, becoming part of the experienced industrial giant. Eurotherm joins US-based Watlow in 2023, becoming part of the experienced industrial giant.

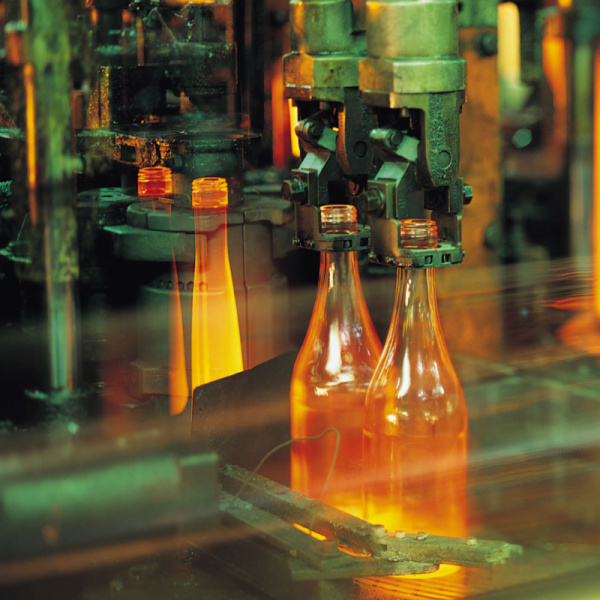

Watlow is well known worldwide as a leader in industrial technology and thermal products. The company designs and manufactures heating solutions. These mainly consist of electric resistance heaters, temperature sensors, power controllers and ancillary software.

Watlow works with its customers to optimise thermal performance, reduce design time and improve the efficiency of applications. Watlow has 100 years of experience in many industries including semiconductor processing, environmental technology, power generation, diesel emissions, medical and food manufacturing.

Other articles and videos about Eurotherm products: