Temperature has a profound effect on all natural elements and processes, from the germination of a grain of wheat to the dramatic melting of Antarctic glaciers. Temperature plays an equally important role in our daily lives. This is very well reflected in the thermal sensations of the body and the comfort levels of the environment. To accurately determine the temperature of a liquid, solid or gaseous substance, a variety of temperature sensors are available to measure and monitor the temperature. Of course, each of them uses different technologies and principles to make the most accurate measurements possible. However, they can malfunction or even fail for a variety of reasons such as corrosion, vibration, calibration or other errors. In this article, find out how the 4 most widely used types of temperature sensors can prevent common problems.

Table of contents:

Temperature sensors are used for a variety of purposes in virtually every industry around the world. They can be found in both everyday life and industry. In essence, temperature sensors provide an input to a system to determine the approximate or exact temperature of a specific object or environment. Let us list just a few examples of where these sensors are used:

Temperature sensors are used for a variety of purposes in virtually every industry around the world. They can be found in both everyday life and industry. In essence, temperature sensors provide an input to a system to determine the approximate or exact temperature of a specific object or environment. Let us list just a few examples of where these sensors are used:

In industry, in the monitoring of various equipment and the environment, e.g. in the manufacture of household appliances.

In industry, in the monitoring of various equipment and the environment, e.g. in the manufacture of household appliances.

Temperature sensors are relatively simple and can be found in equipment and devices of varying degrees of complexity. Sensor response and accuracy can range from low to extremely high temperatures. In order for system maintainers to be competent in selecting different technical solutions depending on the characteristics of the system and the type of application, it is necessary to understand the breakdown of temperature sensors. They can be grouped as follows: thermistors; resistance temperature detectors (RTD); thermocouples; semiconductor sensors. In the following chapters, we will provide a more detailed introduction to each of these types.

Thermistors, or Thermal resistors, can be very small in size. They mainly consist of a sensing element, which may be coated with epoxy or glass material. They usually have 2 wires designed to make a connection to an electrical circuit. They detect temperature by changes in the electrical resistance. Thermistors are available as NTC or PTC. Their cost is most often low. PTC thermistors are rare because they are made of special materials that can be used at high temperature fluctuations. The most efficient operating range is -50 to 250 °C for glass thermistors or 150 °C for conventional thermistors.

Thermistors, or Thermal resistors, can be very small in size. They mainly consist of a sensing element, which may be coated with epoxy or glass material. They usually have 2 wires designed to make a connection to an electrical circuit. They detect temperature by changes in the electrical resistance. Thermistors are available as NTC or PTC. Their cost is most often low. PTC thermistors are rare because they are made of special materials that can be used at high temperature fluctuations. The most efficient operating range is -50 to 250 °C for glass thermistors or 150 °C for conventional thermistors.

RTDs are also known as Resistance Temperature Detectors (RTDs) and work in a similar way to thermistors. The temperature is measured with an ohm resistance. Like thermistors, resistance temperature detectors are connected to a circuit, but have a much wider temperature range. They can also measure extreme temperatures.

RTDs are also known as Resistance Temperature Detectors (RTDs) and work in a similar way to thermistors. The temperature is measured with an ohm resistance. Like thermistors, resistance temperature detectors are connected to a circuit, but have a much wider temperature range. They can also measure extreme temperatures.

RTDs consist of plastic or metal wire if more precision is required. The wire is wrapped around a ceramic or glass core. The most accurate RTDs are made of platinum, while some of the cheapest will be made of copper or nickel. RTDs made of platinum provide very accurate linear output from -200 to 600 °C and of course they are also much more expensive.

These semiconductor-based sensors are most commonly used in integrated circuits (ICs). Using two identical diodes with a temperature sensitive voltage and current characteristic, temperature changes are monitored. They provide a linear response, but it should be recognised that they have the lowest accuracy of the basic sensor types. In contrast, these temperature sensors also have the slowest response over the narrowest temperature range. The temperature range from -70 °C to 150 °C.

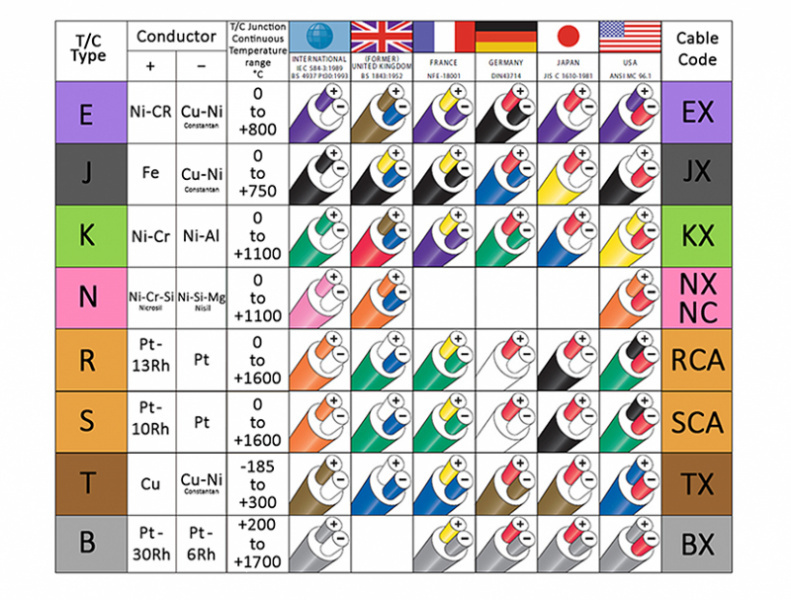

A thermocouple is a sensor for measuring temperature. It is very simple - two wires of different metals are connected or soldered together at a point called the thermal junction. To measure temperature with a thermocouple, this thermal junction point must be attached to the surface where the temperature is to be measured. The change in temperature generates a voltage which is used as a reference to the temperature table, which ultimately outputs a fixed temperature. Thermocouples are widely used in various industrial sectors as well as in scientific projects.

A thermocouple is a sensor for measuring temperature. It is very simple - two wires of different metals are connected or soldered together at a point called the thermal junction. To measure temperature with a thermocouple, this thermal junction point must be attached to the surface where the temperature is to be measured. The change in temperature generates a voltage which is used as a reference to the temperature table, which ultimately outputs a fixed temperature. Thermocouples are widely used in various industrial sectors as well as in scientific projects.

The most popular applications for thermocouples are in the industrial sector, steel mills, power generation, pharmaceuticals, biotechnology, cement production and oil and gas processing.

Thermocouples have a large temperature range, i.e. from -200 to 1750 °C, and a relatively low cost, making them a popular choice in many industries. Two different metals or alloys form different types of thermocouples. Each combination has its own properties and applications.

| Thermocouple type | Short-term use t° range | Long-term use t° range |

|

Type B |

0 – 1820 °C | 200 – 1700 °C |

|

Type E |

-40 – 900 °C | 0 – 800 °C |

|

Type J |

-180 – 800 °C | 0 – 750 °C |

|

Type K |

-180 – 1300 °C | 0 – 1100 °C |

|

Type N |

-270 – 1300 °C | 0 – 1100 °C |

|

Type R |

-50 – 1700 °C | 0 – 1600 °C |

|

Type S |

-50 – 1750 °C | 0 – 1600 °C |

|

Type T |

-250 – 400 °C | -185 – 300 °C |

When choosing temperature sensors, we recommend you pay attention to the following aspects:

Temperature range - many temperature sensors can provide different types and ranges of measurements, but not all ranges will be equally accurate. Before purchasing a particular temperature sensor we recommend that you check the range and compare it with the needs of your project.

Accuracy and stability - you probably also need a certain degree of accuracy and stability. The following aspects need to be taken into account as, for example, thermocouples have a higher long-term stability variation than RTDs and thermistors. NTC thermistors usually have the highest accuracy if they are glass coated.

Workplace size - sometimes the size of the workplace can also be a factor in choosing a temperature sensor. If space is at a premium, then a smaller sensor will logically be required.

We would like to emphasise that ZTF Lāsma offers a wide range of temperature sensors. Thermocouples and thermistors are the most commonly used, but there are also non-contact, digital, quartz and various other combination temperature sensors.

We would like to emphasise that ZTF Lāsma offers a wide range of temperature sensors. Thermocouples and thermistors are the most commonly used, but there are also non-contact, digital, quartz and various other combination temperature sensors.

Many of the sensors are manufactured by companies such as Nivelco, Pixsys, Czaki, Aplisens, Seneca and others. Check out our full range of temperature sensors at lasma.eu or contact us.

You can see the temperature sensors in stock here:

Other articles and videos on temperature sensors: