SICK has launched its latest generation distance sensor OD2000, which combines high-precision measurements at an affordable price. This sensor is very compact and easy to integrate anywhere. It should be pointed out that this distance measurement sensor offers countless opportunities not only for manufacturing companies but also for machine builders. For the advantages and technical specifications of the sensor, please read below.

The new SICK OD2000 distance sensor family includes six sensors with different measuring ranges from 25 mm to 1200 mm. This provides versatile applications for a wide range of tasks, including demanding and high-speed measurements, regardless of the surface, texture, or color of the object. The SICK OD2000 can solve complex positioning tasks with background suppression where precise distance measurements or small hysteresis settings are required.

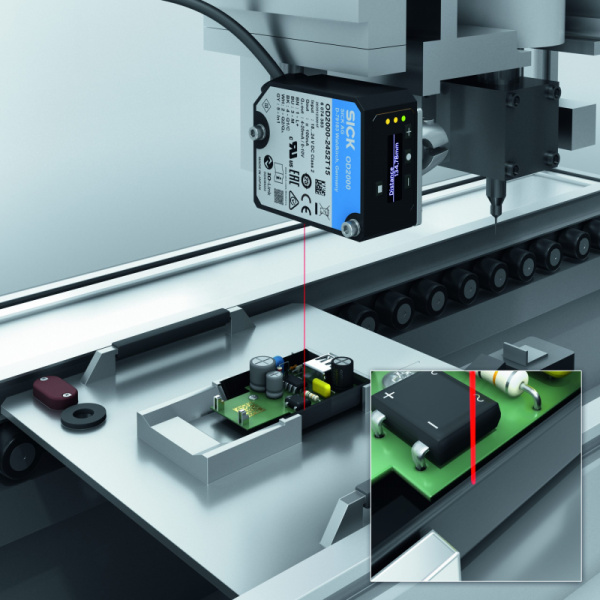

The SICK OD2000 is ideal for manufacturing companies or machine builders who value the sensor's versatility and simplicity of installation. The OD2000 distance sensor is suitable for a wide range of positioning tasks in manufacturing, performing high precision measurements, detecting even the smallest height differences in the micrometer range.

Especially suitable for positioning tasks in production processing and assembly processes and robot operation.. Automating measurement and positioning operations, allowing flexibility to adapt to different materials and conditions without human intervention. The use of accurate distance sensors improves the quality and accuracy of the production process, reducing production costs and time.

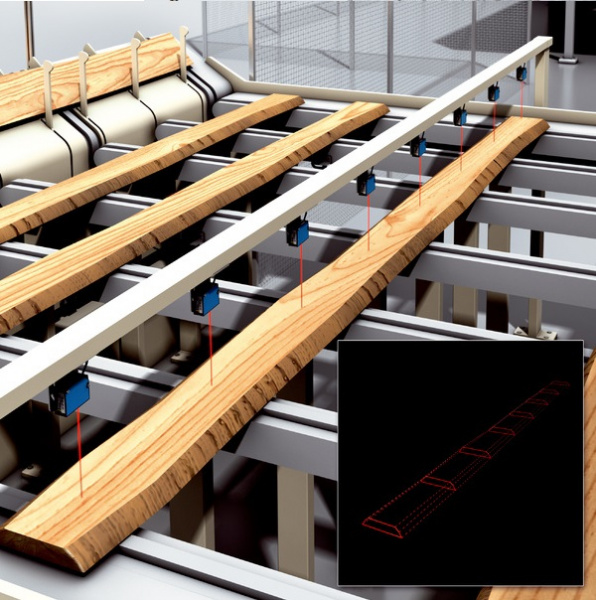

As well as measuring the edges of raw boards, the use of sensors in the wood industry is important because it affects the quality, cost and usability of the lumber. The measurement of raw board edges is important in the timber industry as it affects the quality, cost, and usability of lumber. Measuring edges helps to optimize the sawn timber production process and to reduce waste scrap.

As well as measuring the edges of raw boards, the use of sensors in the wood industry is important because it affects the quality, cost and usability of the lumber. The measurement of raw board edges is important in the timber industry as it affects the quality, cost, and usability of lumber. Measuring edges helps to optimize the sawn timber production process and to reduce waste scrap.

This sensor is particularly useful for large manufacturing companies in quality control processes, as well as for positioning and object distance determination. The use of precise positioning sensors or measuring devices in the quality control of production processes achieves high accuracy and repeatability, ensuring that the products produced meet the standards and specified requirements. This increases production efficiency and reduces product defects, leading to improved product image, increased competitiveness, and a loyal customer base.

This sensor is particularly useful for large manufacturing companies in quality control processes, as well as for positioning and object distance determination. The use of precise positioning sensors or measuring devices in the quality control of production processes achieves high accuracy and repeatability, ensuring that the products produced meet the standards and specified requirements. This increases production efficiency and reduces product defects, leading to improved product image, increased competitiveness, and a loyal customer base.

Thanks to the Plug and Play concept, the distance sensor can be integrated anywhere very quickly. The sensor features easy and intuitive adjustment and configuration via the sensor's OLED display.

Thanks to the Plug and Play concept, the distance sensor can be integrated anywhere very quickly. The sensor features easy and intuitive adjustment and configuration via the sensor's OLED display.

The IO-Link interface and the SOPAS software provide additional functionality and versatile integration options for the sensor while providing diagnostics and condition monitoring. With IO-Link communication, existing configuration parameters can be integrated into any other new SICK OD2000 sensor, simplifying installation.

| Measuring range: | six sensors with different measuring ranges: 25 mm...1200 mm |

| High accuracy: | linearity: ± 10 µm ... ± 3 mm and repeatability: 0.1 µm ... 100 µm |

| High measurement frequency: | up to 7.5 kHz for high-speed process measurements |

| Digital output: | 2x PNP/NPN (selectable) |

| Analog output: | 1x 4 .. 20 mA/0 .. 10V (selectable) |

| Operating temperature: | -10 °C ... +50 °C |