Despite the company's size and type of operation, industrial production currently provides a significant competitive advantage. The new production processes are mostly digitized and oriented towards the e-environment. These modern processes have increased the demand for various types of automation products such as limit switches, safety components and various types of sensors. The value and importance of these products is evidenced by the recent deal between Telemecanique Sensors and Yageo Corporation, which amounted to 723 million euros.

In this article, you will learn how reliable limit switches and sensors from Telemecanique Sensors can be useful for you.

Telemecanique Sensors was founded in France in 1924. The company specializes in the development and production of sensors and their technologies, specifically designed for factory automation. In almost 100 years, it has seriously developed and proven itself in the market. On August 1, 2023, Taiwanese company Yageo acquired the Telemecanique Sensors brand and all its patents from Schneider Electric. The approximate amount of the transaction was EUR 723 million. This transaction will significantly expand Yageo cooperation with industrial customers around the world.

According to Telemecanique Sensors Nordic and Baltic region manager Christian Balle, the acquisition means that the company will now be able to assert itself even more in the market. It should be mentioned that Yageo, Taiwan electronic component and service provider, specializes in electronic components such as capacitors, inductors, transformers, relays, antennas, wireless components and circuit protectors. This means that the huge international sensor company has fallen into the hands of a powerful owner. Read more about this in our previous article Telemecanique Sensors: World Class Sensors. However, in this article we will take a look at the main product groups and applications of the company.

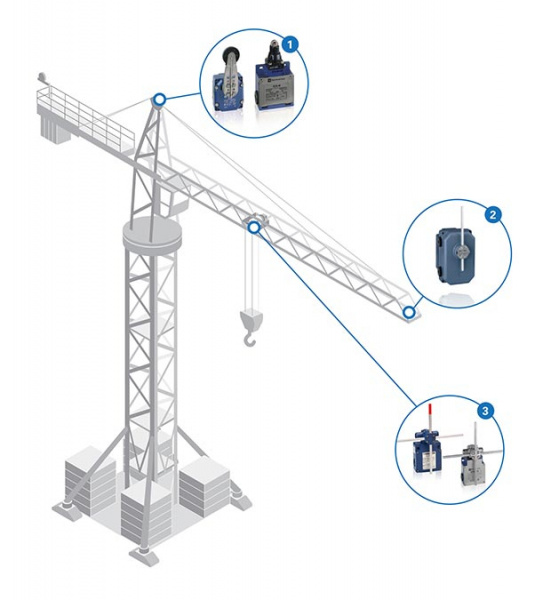

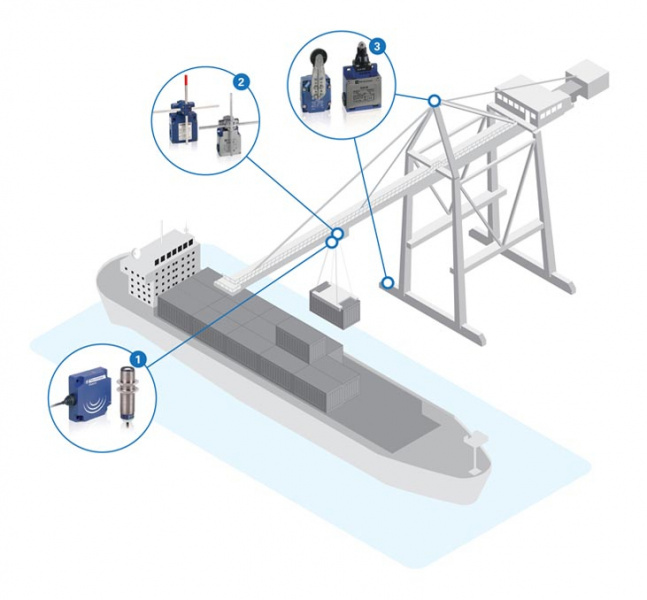

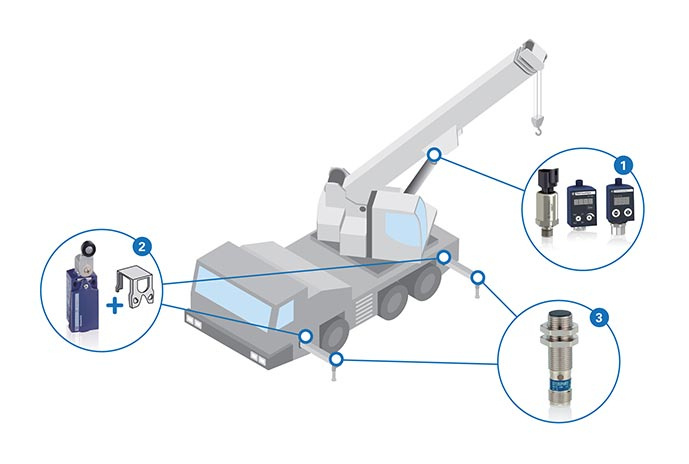

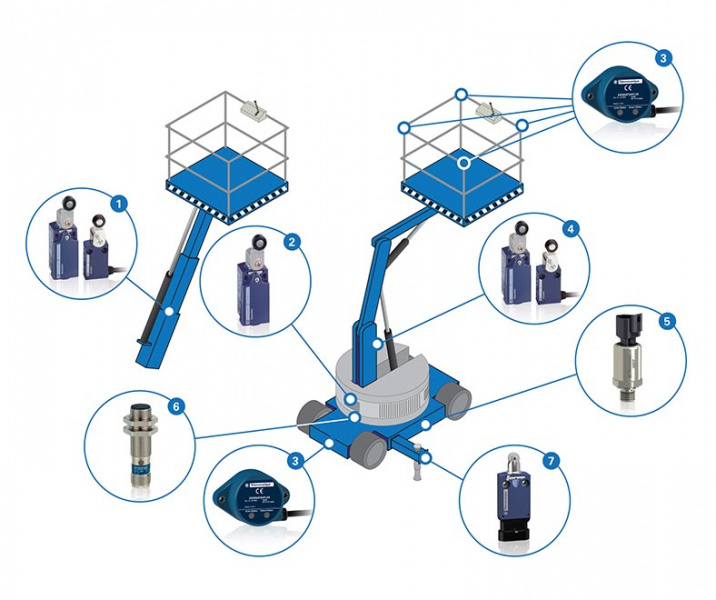

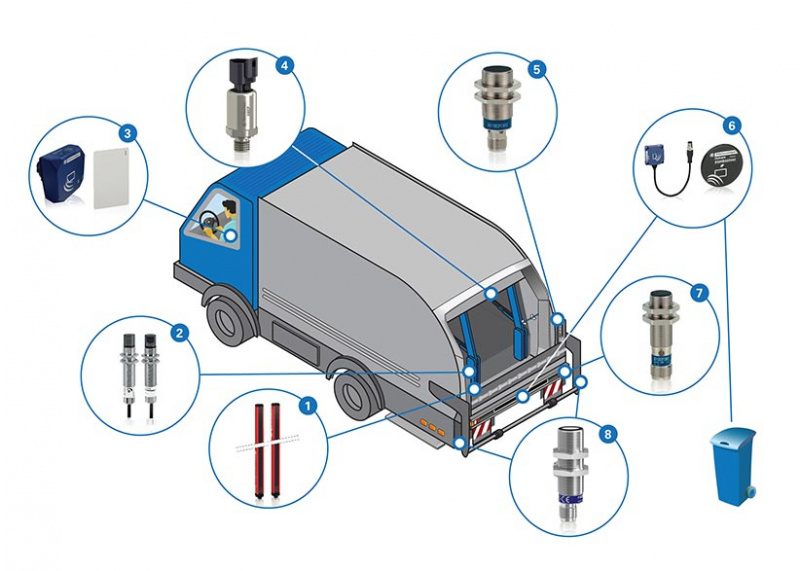

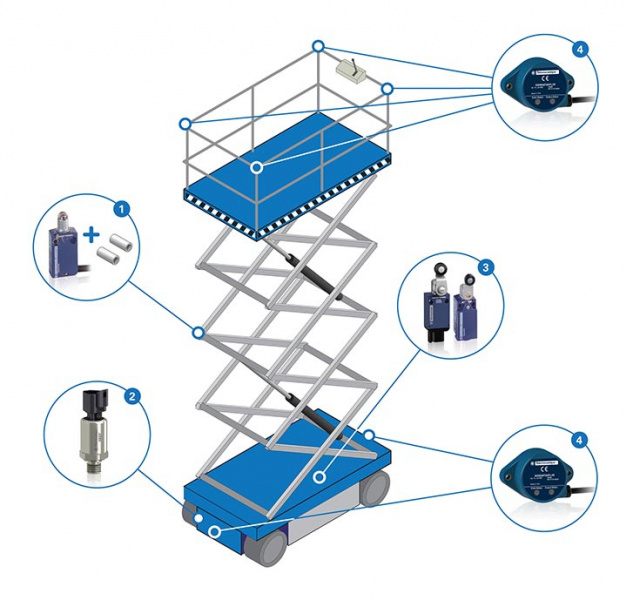

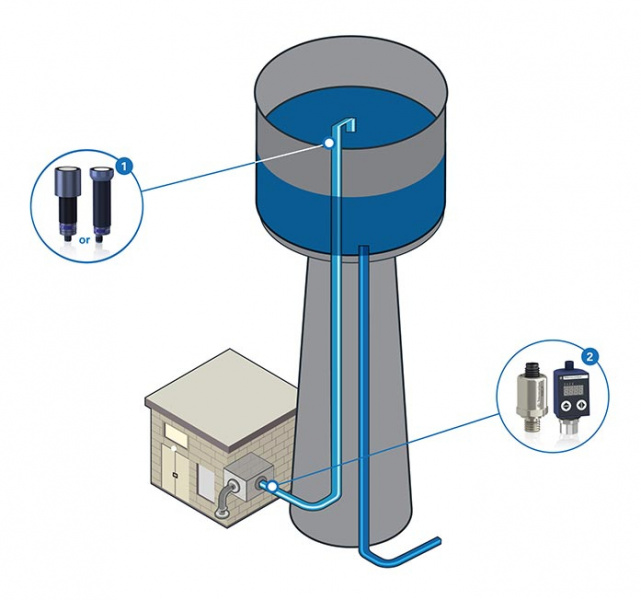

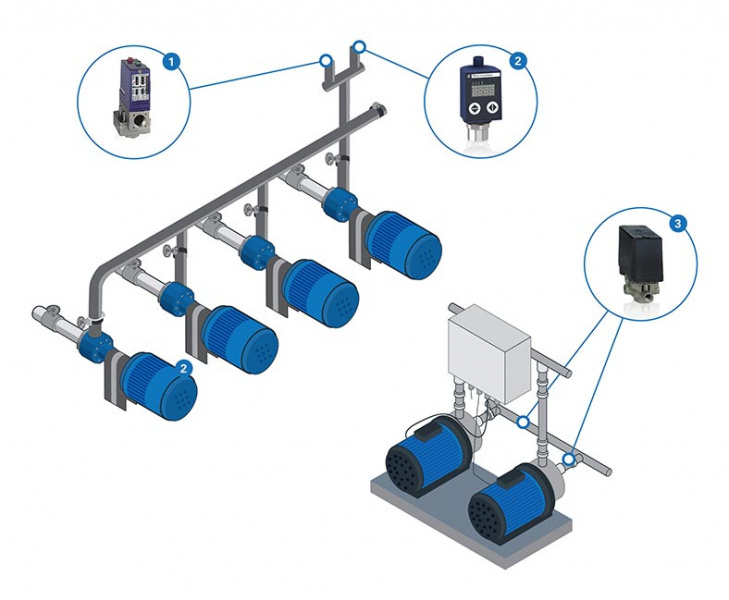

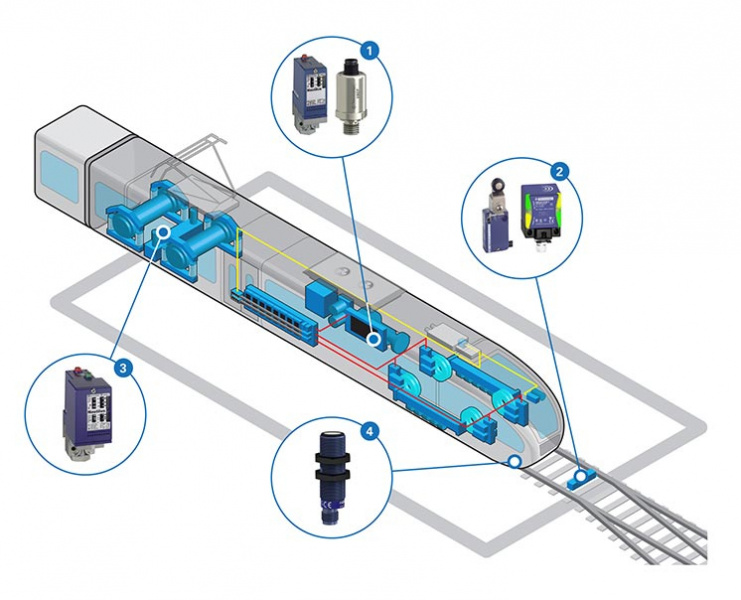

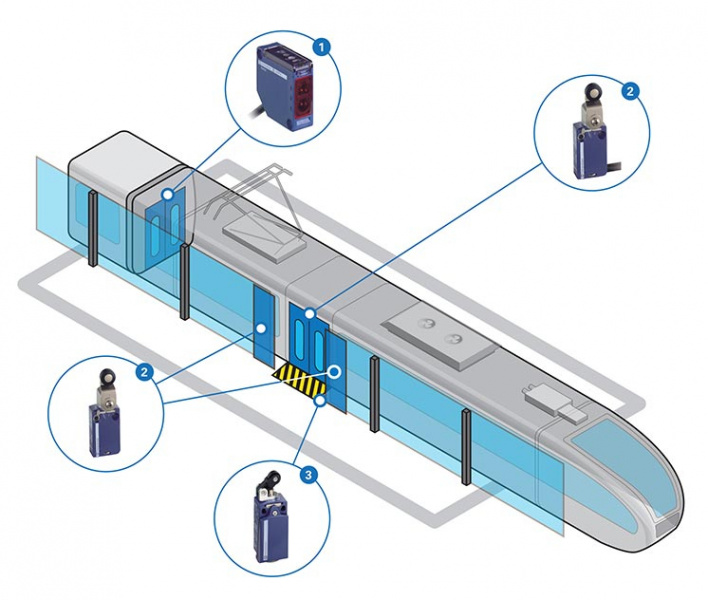

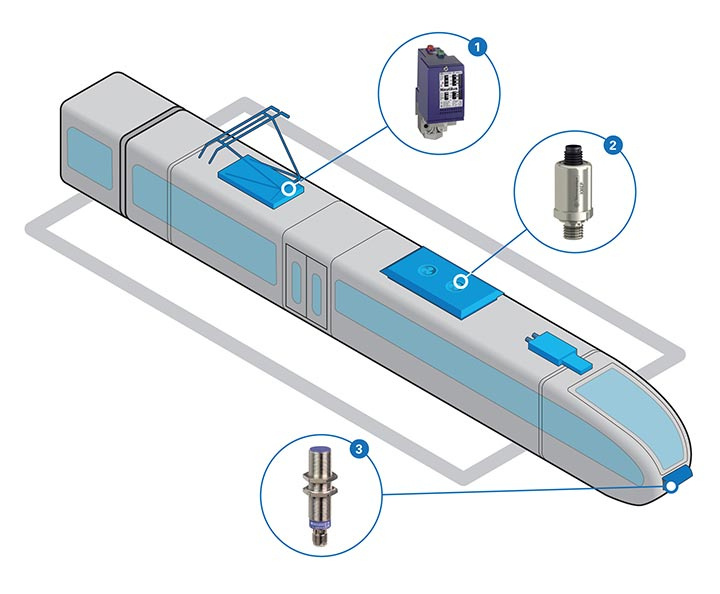

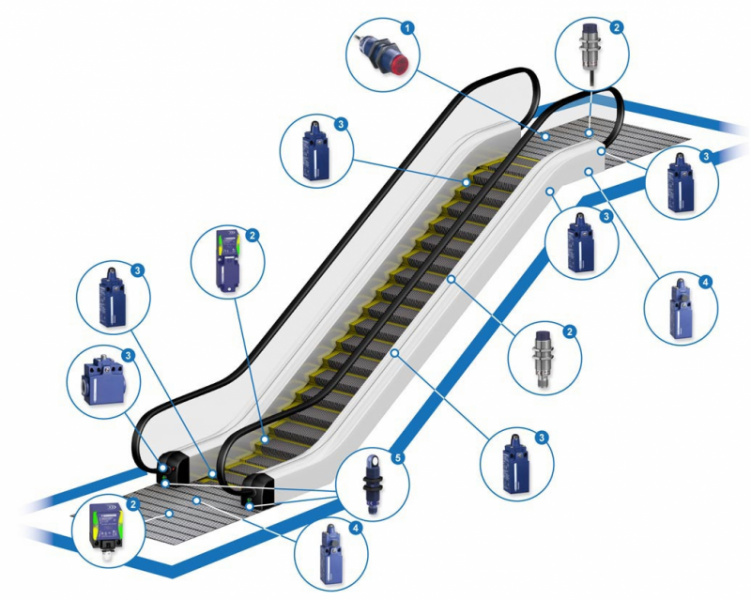

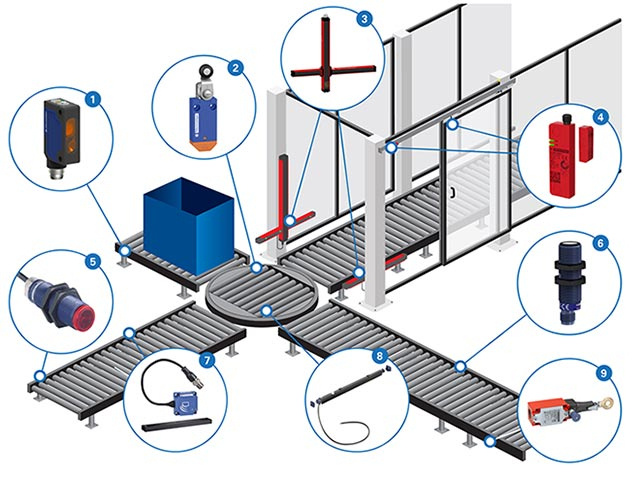

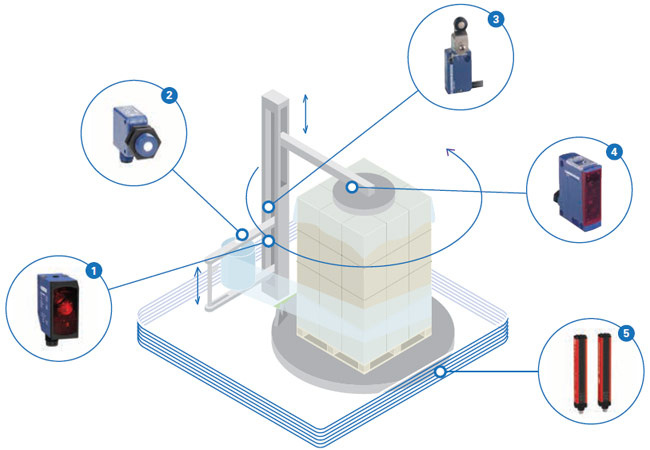

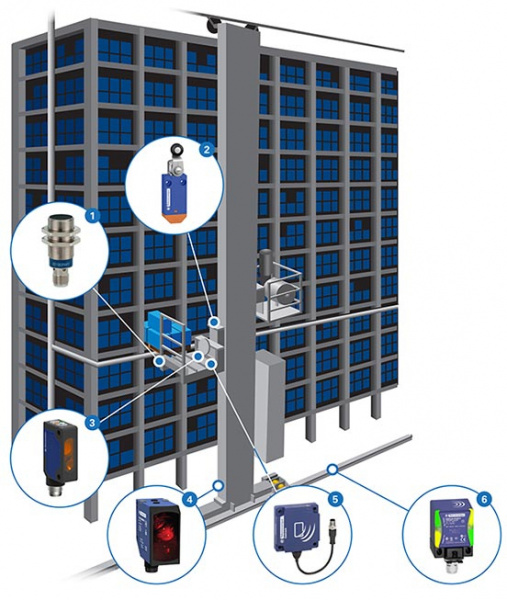

It should be mentioned that several limit switches, sensors and safety components are usually used within one project. Some projects require certain safety certifications, some require sensors to withstand high pressure, and other projects require the use of certain types of connectors. Telemecanique Sensors has been an expert in sensors and limit switches for over a century. Your company will definitely be able to receive project-appropriate products that will be suitable for the needs of your industry. Below, see visual examples of where these products are used.

This product line is intended for equipment that ensures lifting and lowering of heavy loads in a limited area. The products are adapted for equipment that is not intended for transporting people.

This group includes both transport vehicles and lifting equipment built into vehicles. Telemecanique Sensors is the first to achieve both Sil2 certification for industrial equipment safety and E2 certification for mobile equipment.

A product line designed for water pumping. Especially suited to the required standards and purposes for water pumping applications worldwide.

A line of sensor products specifically addressing the required standards, constraints and objectives of rail systems around the world. It ensures increased safety according to the new EN455 standard.

A product line designed for the escalator and elevator industry. These products are created especially in compliance with the necessary standards for escalator and elevator systems. It should be emphasized that they are compact and easy to install.

Telemecanique Sensors is a world-class brand offering a wide range of products for handling materials and packaging. Whether detection, storage or handling solutions are required, for a conveyor system or a wrapping machine.

The company boasts a rich history of limit switch innovation that dates back to the early 1900s. Currently offers the widest range of mechanical limit switches in the world. Whether your production equipment requires an IEC, NEMA, safety, wireless or battery-free limit switch, the company's unmatched selection of mechanical limit switch and connector options makes it easy to find a solution for any equipment design.

The range of limit switches is very wide. It is divided into two parts - standard and specialized limit switches. On the other hand, the classification of standard limit switches is divided as follows:

In order to increase the quality and volume of the produced products in the long term, investments in equipment modernization and employee growth are necessary. ZTF Lāsma engineers emphasize that one of the most important steps in equipment modernization is the correct selection of the sensor and its precise installation. Sensors are often called the hearts of production equipment, because there is nothing in automation without them. Let's start by saying that we offer a diverse range of sensors. More on them below.

Inductive sensors - intended for object detection without contact with metal objects. Sensors are used to detect the presence or absence of metal objects at a distance of up to 60 mm. They work in response to metal or magnetic properties and are common in various production lines.

Capacitive sensors - more intended for detecting insulation or conductive materials. With these non-contact sensors, it is possible to detect the presence of any other type of material at a distance of up to 20 mm. They can be used, for example, to control the supply of materials or to detect liquid levels. Like inductive sensors, these are best-in-class immune to harsh industrial environments.

Industries where inductive and capacitive sensors are widely used are railways, elevator systems, logistics, material handling, production lines, packaging production, food and beverage industry, robotics, etc.

Photoelectric proximity sensors - basically consist of a light beam transmitter (light emitting diode) and a light sensitivity receiver (phototransistor). Sensors are designed to detect an object using infrared or ultraviolet rays without any contact with the object. Photoelectric proximity sensors are perfect for material handling, packaging, labeling, assembly, elevators and escalators, or the food and beverage industry. The easy selection of their products will make the work easier, as the technical parameters are clearly understood.

Ultrasonic sensors - designed for non-contact material detection, regardless of the object's light, shape, texture, color, transparency, dust or density. These sensors use ultrasonic waves to determine the distance or presence of an object and their location. They have high immunity to electromagnetic interference. Ultrasonic sensors can withstand even the harshest industrial environments. This range of sensors even includes long-range detection models.

Pressure control sensors - or electronic pressure sensors for the control circuit are basically intended for detecting an object in contact with a liquid. Thanks to their pressure measurement technology and fluid input material, pressure transmitters and pressure switches can be used to monitor air, fresh water, hydraulic oils and coolants.

Cloud-connected sensors - designed for wireless solutions as they integrate with PLCs and data acquisition systems to enable automatic operation and data analysis. The sensors are ideal for hard-to-reach places and objects without electricity. They help collect data from remote devices and send it to a computer or mobile device via the Internet. XIOT Cloud Connected Sensors is based on LPWAN (Low Power Wide Area Network) technology powered by Sigfox (Network Overlays in Europe). The sensor provides accurate and reliable data on installations in real time.

The brand offers many safety components that help maintain safety in the workplace by identifying hazardous conditions, thus ensuring the safety of workers and equipment.

Interlocking Safety Switches - Protect both equipment and production operators by stopping heavy or light industrial equipment using the best solutions from the XCS line of safety interlocking switches. It provides a range of options to avoid dangerous situations.

Safety switches and sensors in hazardous dust environments - these sensors are intended for areas where the presence of hazardous material (dust) is present in sufficient quantities to create explosive or flammable mixtures. Preventa's range of hazardous dust atmospheric sensors includes a wide range of products including limit, pressure and safety switches as well as inductive and speed monitoring sensors. Telemecanique Sensors is proud to offer a range of sensors that are ATEX and IECEx certified to meet the required safety standards.

Safety Rope Pull Switches - These are designed for machine operators to quickly shut down dangerous machines. It is a cost effective and UL certified safety solution. This allows personnel to react quickly at any point on the conveyor to shut down dangerous machines, protect themselves and equipment. These pull switches are easy to use, easy to install, compact and ergonomic. They meet the necessary requirements for emergency stopping of dangerous machines even in severe conditions.

Safety light curtains – provide effective protection of the operator and automatic shutdown of the machine if the restricted area is violated. Safety light curtains can be used on virtually any hazardous machine that requires area protection for the safety of operators and equipment. Easily configure many shutdown parameters using free software.

Remember, when choosing Telemecanique Sensors products, you will receive the highest technology solutions!