Almost 80% of all dust from production processing is flammable. These dust-like substances are widely present in various production and processing processes. It is important to understand that these substances are capable of creating an inflammable or explosion hazard, making certain workplaces hazardous areas. It may seem unbelievable, but even a 1 mm thick layer of dust can cause an explosion in a confined space if the dust is mixed with air creating an explosive dust atmosphere! As a result, production equipment and installations can be damaged and people working on site can be injured. To limit the above risks, ATEX-certified sensors for explosive atmospheres from Telemecanique Sensors are an excellent solution.

Potentially explosive dusts can be formed in various production processes, such as the production of specific food products (flour or sugar) or the handling of solid materials (sawdust, building materials).

They can also occur during the transportation and handling of bulk materials (grain, various raw materials). All companies involved in such production face risks of fire and explosion.

Let us highlight the main areas that are at increased risk of explosion or fire. These are as follows:

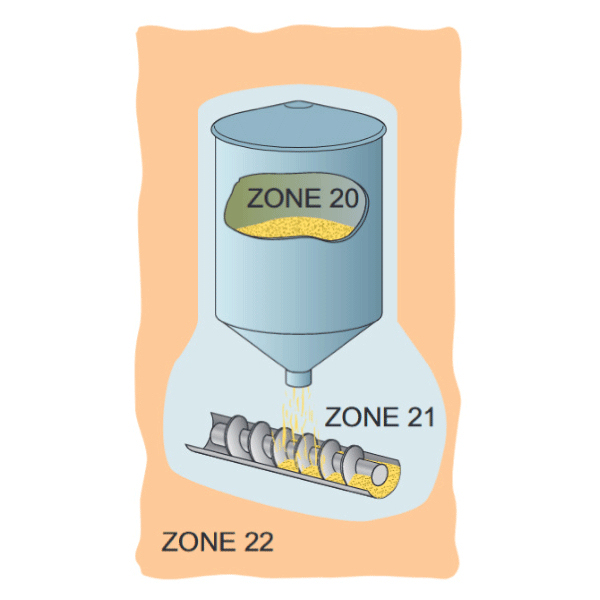

An explosive atmosphere is defined in the Ex series of standards as a place where flammable substances mixed with air, gas, vapour, mist or dust, if ignited, can spread uncontrollably throughout the non-combustible medium of the mixture. Explosive workplaces are divided into zones. This is based on the frequency of occurrence and duration of the explosive atmosphere. The international classification of hazardous areas is divided into dust areas.

| Zone 20 | Zone 21 | Zone 22 |

| Extremely Dangerous Area | Dangerous Area | Low danger area |

| A zone where an explosive atmosphere in the form of flammable dust clouds in the air may occur continuously, prolonged, or frequently. | A zone where an explosive atmosphere in the form of flammable dust clouds in the air may occasionally occur during normal operation. | A zone where an explosive atmosphere in the form of a cloud of combustible dust is unlikely to occur, but if it does, it is only likely to occur for a short period of time. |

Environmental safety must be taken into account to reduce risks in explosive work areas. One way to do this is to introduce different types of dust collection structures and extraction hoods and to ensure that production areas are cleaned regularly, as a cleaner working environment helps to reduce the accumulation of dust. Using appropriate sensors for explosive atmospheres can create safer working conditions.

All electrical equipment and components must comply with the International Standard for safe operation in explosive atmospheres. This applies in particular to equipment that may present a risk of sparks and ignition.

All electrical equipment and components must comply with the International Standard for safe operation in explosive atmospheres. This applies in particular to equipment that may present a risk of sparks and ignition.

The ZTF Lasma range includes a variety of limit switches and sensors from Telemecanique Sensors. Their correct application reduces the risks of fire or explosion and increases the safety of your employees, production equipment, buildings, and installations.

Telemecanique Sensors explosive dust atmospheric sensors comply with the global international standard IECEx and the latest European ATEX directive. By choosing these sensors for your equipment located in an explosive dust area, you will receive 100% tested and certified sensors. We can confidently say that they meet the required safety standards.

Telemecanique Sensors explosive dust atmospheric sensors comply with the global international standard IECEx and the latest European ATEX directive. By choosing these sensors for your equipment located in an explosive dust area, you will receive 100% tested and certified sensors. We can confidently say that they meet the required safety standards.

ATEX is a derivative of the term "atmospheric explosives" (ATmosphere EXplosible). This certificate is mandatory for all products sold in the European Union for use in explosive atmospheres. ATEX consists of two European Directives that define the specific working conditions and the specific types of equipment allowed for work in hazardous environments.

IECEx stands for International Electrotechnical Commission for Explosive Atmospheres. In order to obtain the relevant IECEx certificate, the product must pass the IECEx monitoring process. This ensures that it meets the necessary safety requirements.

The main difference between the certifications is that ATEX certification only applies to EU countries, while IECEx certification is used worldwide. This means that IECEx certification is more widely known and used than ATEX certification. Another difference between these certifications is that ATEX is based on legal requirements, whereas IECEx is based on industry-accepted standards.

Telemecanique Sensors' Explosive Dust Atmospheric Sensors range includes a wide range of products including limit pressure and safety switches as well as inductive and speed monitoring sensors.

A more detailed list is below:

A more detailed list is below:

For more information about the best solution for your needs, please contact us or visit the product catalog on our website.