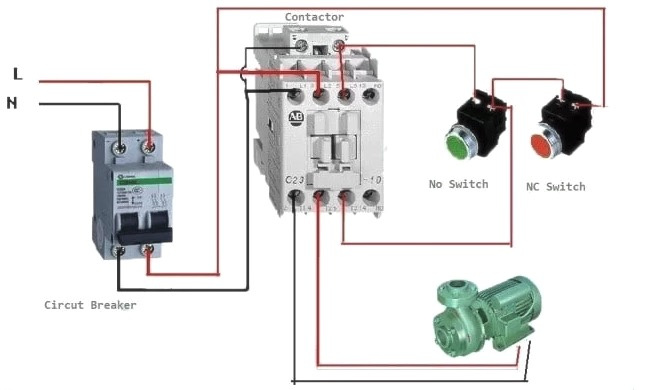

When working with electrical networks, it is always necessary to switch the power supply on or off periodically. For this purpose, professionals use contactors - electromagnetic devices with a very long lifetime and high load capacity, designed to switch electrical circuits on and off up to thousands of times per hour. Mechanical switches or relays are traditionally used for this purpose in everyday work, but have the disadvantage of limited power handling and capacity. Therefore, contactors are used in large electrical systems where high voltage resistance is required. Especially important, such contactors allow loads to be controlled remotely - they are remotely controlled switches that automate processes and operations.

Table of contents

Contactors are most commonly used for high current loads - they can withstand currents in excess of 5000 A and outputs in excess of 100 kW. These switching devices, or electromagnetic contactors, have a wide range of applications. From controlling loads on high voltage power lines to the operation of tram and train power lines. They are also used to switch, for example, street lights on and off. They are widely used in various industrial sectors and in construction, where powerful electric motors, work equipment and other devices need to be powered. Even in our own homes, they are essential for switching on or off heating systems or electric motors, water heaters or water pumps.

Contactors are most commonly used for high current loads - they can withstand currents in excess of 5000 A and outputs in excess of 100 kW. These switching devices, or electromagnetic contactors, have a wide range of applications. From controlling loads on high voltage power lines to the operation of tram and train power lines. They are also used to switch, for example, street lights on and off. They are widely used in various industrial sectors and in construction, where powerful electric motors, work equipment and other devices need to be powered. Even in our own homes, they are essential for switching on or off heating systems or electric motors, water heaters or water pumps.

Contactors are essential to provide additional electrical safety and to protect against sudden outbreaks of fire on power lines or from the electrical equipment itself. So if a contactor is used as a magnetic starter for an electric motor, it usually also provides a number of other safety steps - current cut-off, protection against short-circuits, overloads and undervoltage levels.

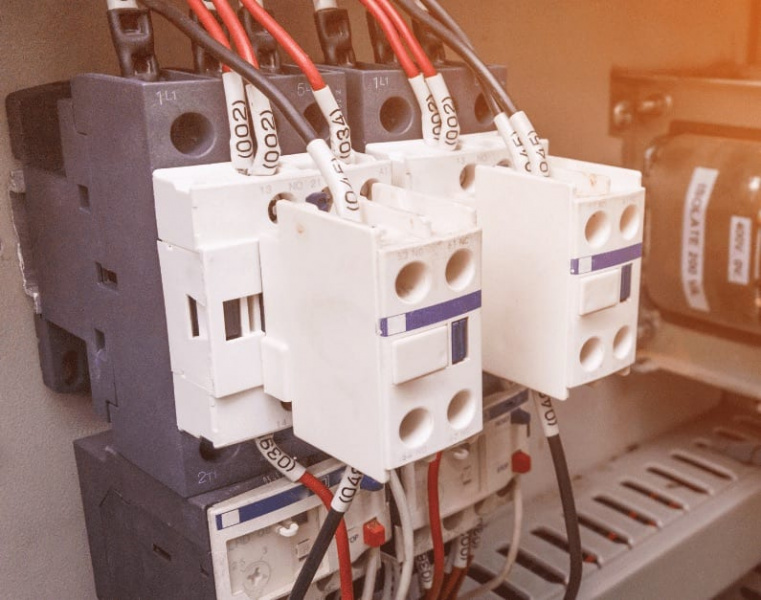

Those who have had closer contact with contactors will know that these devices are characterised by their very compact size, making them easy to install and use (even in the field), and can be connected to any mains and in any environment. They are quiet, even with high power supplies.

Contactors also have a more subtle division, each with its own set of functions and applications - AC contactors, DC contactors and high-frequency AC contactors. How do they differ?

This means that they can be switching, de-energising or toggling contactors, as well as power, reversing, directional, time delay and other functionalities. In addition, devices can be switched not only in one, but even in several electrical circuits.

The contactors can interrupt a wide range of currents - from a few amperes (10A or 16A) to thousands, as well as voltages - from 24V, 42V, 110V, 220V/230V and 380V to thousands of volts. They are controlled by an auxiliary circuit whose voltage must be lower than the operating voltage and correspond to 24V, 42V, 110V, 220V or 380V.

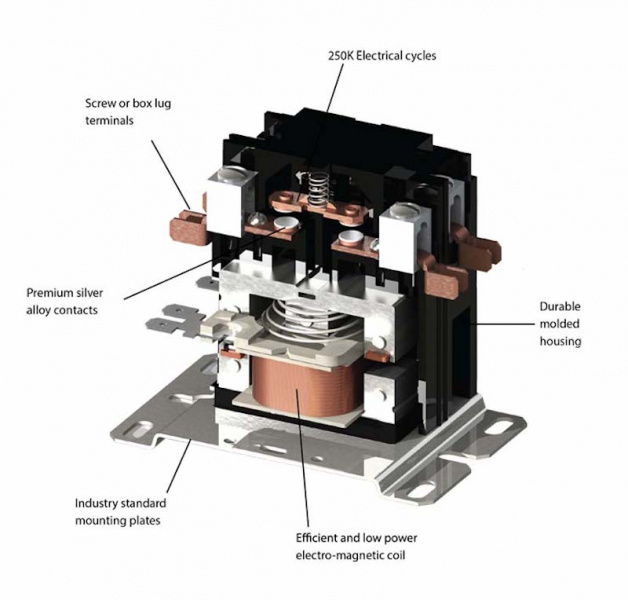

In terms of design, there are few differences between the two contactors, but they use different coils and voltages. They also vary in size, from hand-held to larger. The body of the contactors provides a very safe protection against overheating, explosions and, in general, against people accidentally touching any conductive parts of the circuit-breaker. It also prevents dirt or moisture from entering the contactor.

The main elements of a contactor are a coil and an electromagnet. Depending on how the contactor is set, it will perform a certain action on the contacts of the switch when power is applied - opening or closing them. The current flowing through it actuates the electromagnet, which generates a magnetic field and thus causes the armature of the contactor core to shift. A closed contact completes the circuit between the fixed and moving contacts, allowing current to flow through these contacts to the load. At moments when the current is removed, the coil switches off and opens the circuit. The contacts of contactors are distinguished by their lightning-fast opening and closing.

Because nothing lasts forever, and contactors are no exception, they need regular checks. Experts recommend replacing the whole contactor and not tampering with the inside. Contacts gradually wear out and after a certain time they may no longer provide accurate operation.

ZTF Lāsma's wide range of modular contactors and accessories includes many different types from well-known and trusted manufacturers such as Schneider Electric and Schrack Technik. They are characterised by high quality and a long service life, a wide range of accessories and components, as well as an attractive price.