The braking module is the equipment by which the most efficient AC motor braking is obtained. The operating principle for such a module is very simple: when switching from the AC motor alternating current, direct current is injected into the stator winding, which causes the braking force in the stator.

For AC motor braking there is a option to use - variable frequency drive, sofstarter with braking function or DC injection module. If we compare all of these three items by functionality than of course - variable frequency drive and sofstarter is used more widely because they have "softstarting" function. It is necessary to understand that DC injection modules are specially designed only to provide breaking. Variable frequency drive and sofstarter does not have special transistors with such a high nominal current value and lifetime as DC injection module transistors. Which means that DC injection module have a lot longer lifetime.

Compared to the softer and the frequency changer, the DC braking module is capable of providing 10 times (!) more frequent braking and will be able to brake the equipment at a high load much faster. The speciality of the DC brake is that it is specially designed to be a modular capable of “injecting” DC into 2 phases at the same time. A sofstarter and a frequency changer can only support DC in one phase. Above all, for this reason, the DC brake module is the most efficient solution.

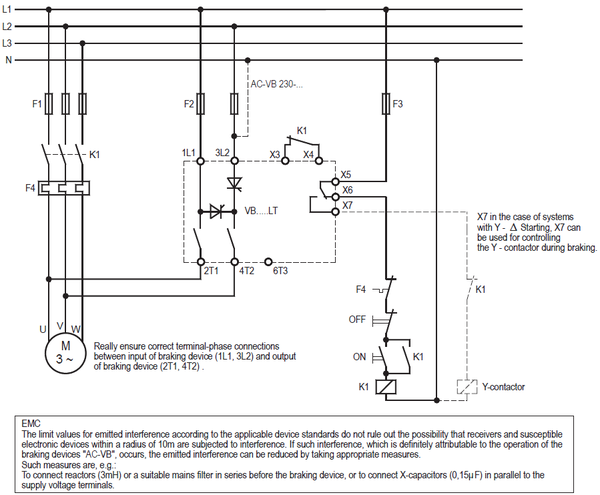

Connection shematic for Peter breaking module:

DC braking modules have proved their efficiency and performance in the industrial automation world, that is the main reason why it is difficult to meet modern equipment today without DC brake modules.

If you have any questions, contact our drive management specialist Kristaps Rossinskis tel.nr. +37129334363 or email kristaps.r@lasma.eu !