Indoor air quality has become a critically important factor in ensuring a healthy and productive environment. Nowadays, people spend the majority (around 80–90%) of their time indoors, which increases the potential risk of exposure to pollutants. Air quality sensors help continuously monitor the air composition, providing timely alerts about pollution and enabling steps to mitigate it. In this article, we will explore how these sensors work, which parameters they measure, and why monitoring them is essential in work and learning environments, as well as examine solutions across various industries.

Poor air quality directly affects our well-being and health. Elevated indoor CO₂ levels are often the main culprit behind fatigue, discomfort, and reduced concentration and productivity. Prolonged exposure to polluted air can cause respiratory illnesses, allergies, and asthma flare-ups. Children are particularly vulnerable – research confirms that indoor air quality significantly impacts children's quality of life and health, and the increasing number of respiratory illnesses among children has led to stricter air quality standards in kindergartens and schools. For example, poor air in classrooms can lead to more frequent coughing, headaches, and fatigue, which in turn worsen children's concentration and learning performance.

Elevated indoor CO₂ levels are often the main culprit behind fatigue, discomfort, and reduced concentration and productivity.

Air quality monitoring allows for the timely detection of harmful pollutants and the implementation of measures to improve the situation. Sensors can detect invisible threats – fine dust particles, volatile organic compounds (VOC), carbon dioxide (CO₂), carbon monoxide (CO), and more – which would otherwise go unnoticed. Timely pollution detection makes it possible to improve ventilation, use air purifiers, or eliminate pollution sources, thereby creating a healthier indoor environment. For example, a CO₂ sensor warning of elevated levels in a classroom prompts ventilation, which immediately improves well-being and cognitive performance.

Industrial air quality sensors use various technologies to detect and measure pollutant concentrations in the air. Below, we will look at some of the most common sensor types and how they work.

CO₂ concentration is often measured using infrared absorption. Modern NDIR (non-dispersive infrared) sensors with dual-wavelength technology can compensate for aging effects and are resistant to contamination, providing accurate long-term measurements. For example, CO₂ sensors from E+E Elektronik use dual-wavelength NDIR technology with automatic calibration, ensuring stability and precision even under varying conditions.

To detect fine dust and particles (such as PM₂.₅ and PM₁₀), laser optical sensors are used, based on the principle of light scattering. As particles pass through a laser beam, the sensor's photodetector registers the intensity of the scattered light – this allows for determining particle concentration and even size. These sensors help quickly identify whether there are hazardous levels of dust, smoke, or other aerosols in the air.

Various methods are used to detect different gaseous pollutants. Volatile organic compound (VOC) sensors are often based on metal oxide semiconductors that change electrical resistance when exposed to VOC molecules. These sensors react to overall air quality (sometimes referred to as “mixed gas” sensors), indicating changes when, for example, cleaning product or paint fumes increase in the room. In contrast, carbon monoxide (CO) detection often uses electrochemical sensors with electrodes that generate electric current in reaction to CO gas. The current strength is proportional to the gas concentration, ensuring accurate measurements.

Although they do not directly measure pollutants, relative humidity and temperature are important indoor environmental parameters. High humidity promotes mold growth, while overly dry air can irritate the respiratory tract. Therefore, many air quality monitors also measure temperature and humidity simultaneously, helping maintain comfortable conditions.

Today, multifunctional sensors and monitors are available that combine several of the aforementioned sensors in one device. For example, there are devices that simultaneously measure CO₂, VOC, PM, temperature, and humidity, providing a complete picture of air quality in real-time. Some industrial duct-type sensors even have a patented multi-chamber design that allows for simultaneous measurement of up to four different variables, such as CO₂, VOC, temperature, and relative humidity, using a single device.

Monitoring multiple parameters provides a comprehensive overview of the air and helps more accurately identify the causes of discomfort.

Monitoring multiple parameters provides a comprehensive overview of the air and helps more accurately identify the causes of discomfort – for example, high PM levels indicate dust or smoke, while elevated CO₂ points to insufficient ventilation. By also monitoring temperature and humidity, it is possible to prevent mold risks in time and ensure comfortable conditions for all occupants of the space.

CO₂, PM, VOC, CO, temperature, and humidity are the most commonly monitored parameters by air quality sensors. Each of these factors has different sources and effects.

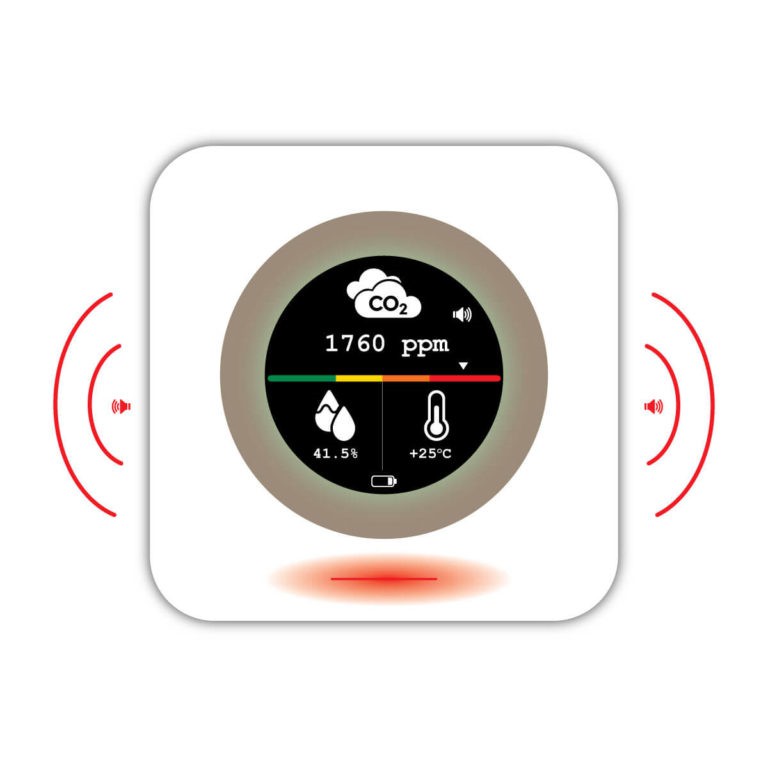

Indoor CO₂ levels mainly rise due to human exhalation and insufficient ventilation, as well as from any fossil fuel combustion (e.g., gas heating boilers). Under normal conditions, outdoor air contains around ~400 ppm CO₂, but in poorly ventilated spaces, levels can exceed 1000 ppm, causing drowsiness and difficulty concentrating. CO₂ monitors provide warnings when the concentration approaches dangerous levels, prompting timely ventilation.

Many schools and offices use CO₂ detectors – devices that indicate air quality using color or sound signals based on CO₂ levels, serving as reminders to open windows. As manufacturers emphasize, CO₂ monitors are indispensable in crowded indoor environments (schools, offices, conference rooms) to maintain alertness regarding air freshness and prevent declines in performance.

These are fine airborne dust particles, which may come from outdoor pollution (traffic particles), smoke, dust, building material particles, etc. PM2.5 (particles ≤ 2.5 microns) are especially hazardous as they can penetrate deep into the lungs. High indoor PM levels may arise from activities like cooking without an extractor hood or polluted outdoor air entering the building. PM sensors help identify dusty and polluted conditions, enabling measures such as cleaning or improving air filtration systems.

VOCs include airborne chemical substances that evaporate from paints, varnishes, cleaning agents, furniture, adhesives, and even some textiles. These substances can cause headaches and irritate the eyes and respiratory system. VOC sensors measure the overall air quality related to organic pollutants and are commonly used to monitor spaces after renovations or areas where chemical products are used. When VOC levels rise, it may be necessary to improve ventilation or restrict the source of pollution (e.g., by storing paints and solvents in sealed containers).

Colorless and odorless, CO is produced through incomplete combustion processes, such as from gas heaters, stoves, or car exhaust in a closed garage. Indoors, CO is especially dangerous, as high concentrations can lead to poisoning or even death. Industrial CO sensors usually operate electrochemically and immediately alert of CO leaks, which is crucial in boiler rooms, parking garages, factories, and other environments where combustion occurs. While CO monitoring is not directly related to "air quality" in the comfort sense, it is critically important for safety.

These two factors affect comfort and health in indoor spaces. Too high or too low a temperature impacts well-being, while incorrect humidity levels can promote mold growth or irritate the respiratory system. Many air quality monitors also integrate thermometers and hygrometers to give users a complete picture. For example, a room with 25°C and 80% humidity presents high discomfort and mold risk, even if all pollutants are within acceptable limits. That’s why comprehensive monitoring (CO₂ + PM + VOC + T + RH) provides the best insight into how to improve the indoor climate holistically.

It’s important to note that pollutants don’t appear by themselves – they always result from some process or source. For instance, CO₂ increases due to human respiration and fuel combustion, VOCs are emitted from chemical products and materials, PM can enter from outside or be generated indoors by combustion and dust, while CO can leak from heating equipment or vehicles. Understanding these sources enables targeted emission control – for example, improving room ventilation, choosing low-VOC building materials, or maintaining cleanliness to reduce dust.

By understanding the sources of air pollution, emissions can be effectively controlled

In workplaces and educational institutions, air quality monitoring is directly linked to productivity, health, and well-being. Poor air quality in offices can lead to so-called “sick building syndrome,” which manifests through headaches, fatigue, eye irritation, and other nonspecific complaints. As a result, employees’ performance and concentration decline.

By installing CO₂ and VOC sensors in the office, companies can monitor in real-time whether ventilation is working effectively enough. For instance, if the CO₂ level in a meeting room exceeds a certain threshold, the system can automatically increase the fresh air supply or notify the facility manager. This improves air exchange and prevents employee fatigue before people even realize there’s an issue.

In schools and kindergartens, air quality is even more critical. When children spend time in polluted or poorly ventilated rooms, they not only feel worse in the moment, but poor air can impact their health in the long term. Studies show that poor IAQ (Indoor Air Quality) contributes to asthma, bronchitis, allergies, and even impairs cognitive development. As a result, many educational institutions are implementing air quality monitors to help maintain a safe environment.

For example, classrooms equipped with CO₂ indicators using color-coded scales (green – good, yellow – attention needed, red – ventilate immediately) provide teachers and students with visual feedback on air freshness. Similarly, if a sensor detects elevated PM2.5 levels (e.g., outdoor pollution or chalk dust), switching on an air purifier might be considered. The result is a healthier environment for children, fewer illnesses, and improved concentration on learning.

Children are in a healthier environment, fall ill less often, and are better able to focus on learning

In industrial and research environments, IAQ monitoring is equally essential. Laboratories, museums, warehouses – each of these spaces has its own air quality considerations. For example, in museums, high humidity or dust levels can damage exhibits, so sensors are used to signal the need for climate regulation. In production facilities, air pollution can affect both employee health and product quality (e.g., microelectronics manufacturing requires clean rooms with minimal PM levels). Industrial sensors ensure these conditions are continuously monitored and compliant with established standards.

The regulatory landscape also drives the importance of IAQ monitoring – many countries have defined air quality standards for public spaces. As highlighted in the Tekon Electronics blog, growing awareness of IAQ’s impact is leading to legislation mandating better air quality in childcare centers and other public buildings. This means that monitoring systems not only protect health but also help institutions meet legal requirements and avoid violations.

Thanks to growing demand, a wide variety of air quality monitoring solutions are available on the market, tailored to different needs.

In this sector, CO₂ sensors are widely used in ventilation systems to implement demand-controlled ventilation (DCV).

For example, E+E Elektronik manufactures built-in CO₂ probes and modules with NDIR sensors that ensure precise CO₂ control in building automation. These sensors are integrated into HVAC systems – when CO₂ concentration in a room exceeds a threshold, the ventilation automatically increases, and vice versa, saving energy when the air is fresh.

The HVAC sector also uses combined sensors that measure CO₂, temperature, humidity, and even air pressure in a single device, allowing for fully automated indoor climate control.

In industrial processes, the focus is not only on comfort but also on process safety and product quality.

For example, in the food industry, it may be necessary to monitor CO₂ levels in storage or production areas to ensure worker safety (CO₂ is used in beverage carbonation, cooling processes, etc.). In heavy industry or chemical plants, VOC and toxic gas sensors are installed to immediately alert of hazardous substance leaks, protecting employees.

In cleanrooms (such as microchip manufacturing), PM particle detectors are critical to ensure dust levels do not exceed strict limits. Importantly, industrial sensors are often equipped with relay outputs or alarm systems that can automatically stop processes or activate ventilation as soon as readings reach dangerous levels.

As previously mentioned, compact indoor monitors (“IAQ monitors”) are popular in these settings, measuring multiple parameters simultaneously and alerting users to air quality via sound or light signals.

For instance, the Lascar Electronics EL-WEM monitor continuously measures PM2.5, PM10, temperature, humidity, VOC, and pressure, calculating the overall air quality index and displaying it with a color ring – from green (“Excellent”) to red (“Poor”). Such devices are useful in offices, schools, theaters, and other public spaces, providing quick feedback on air conditions.

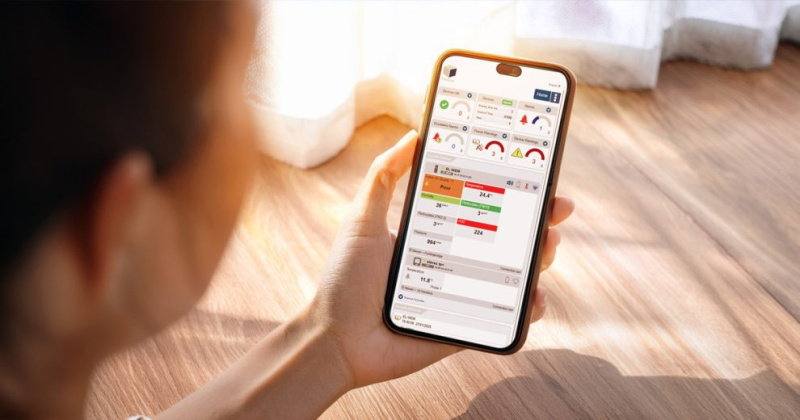

Many of these devices support WiFi or Bluetooth connectivity, allowing data to be uploaded to the cloud and monitored remotely via smartphone. For example, the Lascar EasyLog system enables users to track IAQ data online, receive alerts by email or SMS, and analyze historical data to identify trends. Other manufacturers, like Dostmann Electronic, also offer CO₂ monitors with data logging capabilities – these store measurements that can later be analyzed on a computer to assess air quality changes throughout the day.

It is also worth noting that industrial air quality sensors are used in greenhouses and livestock farming. CO₂ sensors in greenhouses help regulate carbon dioxide supply to plants (CO₂ fertilization), while dust and ammonia sensors in farms help maintain healthy conditions for animals. In this way, sensors promote both increased yields and the well-being of workers and animals in these sectors.

A wide range of sensors and monitors are available on the market, designed for both professional use in industrial environments and simple monitoring at home. Here’s a current overview:

A modern IAQ monitor that measures CO₂, PM1/2.5/10, VOC, temperature, humidity, and pressure. Equipped with an LED status ring, sound alarm, and automatic data upload to the cloud platform (EasyLog Cloud). Operates even during power outages (internal battery).

Wireless CO₂ & Indoor Air Quality Data Logger with Alarms, EL-WEM+, Lascar |

A robust German-made device with an LCD screen that measures CO₂, temperature, and humidity. Features data storage and export (MicroSD) as well as sound alerts when CO₂ levels are high. Convenient for classrooms and presentation rooms.

|

A wireless industrial IAQ sensor measuring CO₂, temperature, humidity, and pressure. Ideal for smart buildings, manufacturing, agriculture, and warehouses. Data is sent to the DUOS Gateway, which can be integrated with cloud platforms.

|

A CO₂ sensor with accurate NDIR technology, available with analog outputs or Modbus RTU. Certain models include LED CO₂ level indicators or LCD displays. A long-lasting and reliable solution for BMS systems.

|

A miniature yet powerful sensor that measures CO₂, temperature, and atmospheric pressure. Data is accessible via I²C and UART interfaces. Ideally suited for OEM applications and integrated products.

|

A portable, battery-powered CO₂ sensor with Bluetooth connectivity and an e-ink display. Also measures temperature, humidity, and pressure. Usable via a free mobile app. Ideal for personal and educational use.

|

A CO₂ monitor developed in Latvia, with an LED warning indicator and e-ink display. Also measures temperature and humidity. Works without a smartphone or app; the battery lasts up to 3 weeks on a single charge.

Luxafor CO₂ Monitor – Air Quality, Temperature, Humidity |

A combined carbon monoxide (CO) and smoke detector with NB-IoT/LTE-M connectivity. Suitable for residential spaces up to 60 m². Designed for ceiling mounting. Alerts via sound signal and transmits data to the LMT platform.

A budget-friendly sensor with a display that measures PM2.5, temperature, relative humidity, and tVOC. Can work independently or connect with the IKEA DIRIGERA hub and STARKVIND air purifiers. Easy to install and styled in classic IKEA fashion.

| Device | Measured Parameters | Connectivity |

|---|---|---|

| Lascar EL-WEM+ | CO₂, PM1/2.5/10, VOC, T, RH, pressure | WiFi, EasyLog Cloud |

| Dostmann AirControl 5000 | CO₂, T, RH | USB (MicroSD export) |

| Tekon DUOS inAir | CO₂, T, RH, pressure | LoRa (DUOS system) |

| S+S AERASGARD® RCO2 | CO₂ | Analog (0–10V / 4–20mA), Modbus RTU |

| E+E Elektronik EE895 | CO₂, T, pressure | UART, I²C |

| Aranet4 | CO₂, T, RH, pressure | Bluetooth |

| Luxafor CO₂ Monitor | CO₂, T, RH | None (local display, USB charging) |

| LMT Elpo | CO, smoke | NB-IoT, LTE-M |

| IKEA VINDSTYRKA | PM2.5, tVOC, T, RH | Zigbee (with DIRIGERA) |

Air quality sensors and data-driven monitoring solutions have become an essential part of modern buildings and many processes. They offer both technical precision and practical benefits – improving human health, well-being, and productivity. As experience shows, timely alerts about poor readings allow for quick action: ventilating rooms, adjusting ventilation systems, turning on filters, or eliminating pollution sources. As a result, the environment becomes safer and more pleasant.

By investing in accurate air quality monitoring solutions, companies and institutions can not only ensure compliance with air quality standards but also create an environment where people feel good and work efficiently.

Whether it’s a factory floor, a school classroom, or an office – a well-chosen and properly used air quality sensor becomes a smart guardian of our everyday environment.