No matter how advanced the PLC or visualization system is, the quality of motion in pneumatics is determined by valves: they control the flow direction, regulate cylinder speed, and maintain the correct pressure. In processes (liquids, gases, granules), valves are literally the 'gateway' between safe production and costly downtime. Below is a practical overview of Festo's range, common mistakes, and selection criteria.

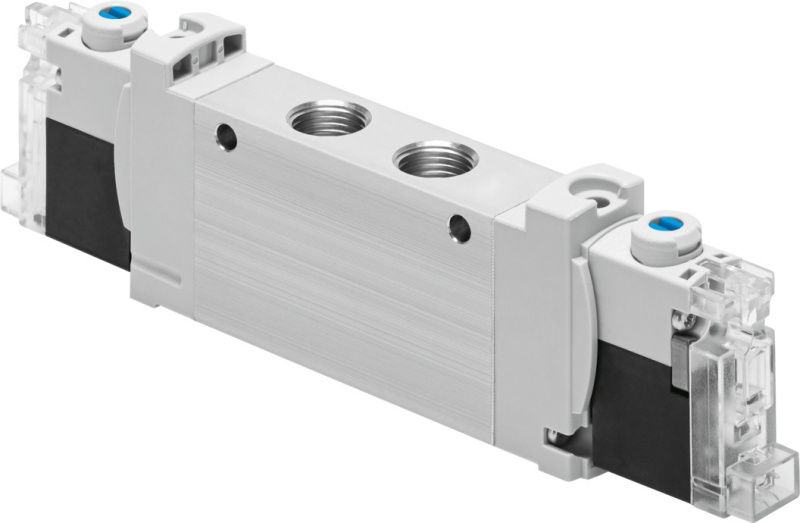

These valves open, close, or switch the paths of compressed air flow (e.g., 2/2, 3/2, 5/2, 5/3, etc.), enabling the movement of actuators such as cylinders, grippers, or other mechanisms.

These valves open, close, or switch the paths of compressed air flow (e.g., 2/2, 3/2, 5/2, 5/3, etc.), enabling the movement of actuators such as cylinders, grippers, or other mechanisms.

The most common solutions are standalone solenoid valves or valve terminals (multiple valves in a bus system with shared control).

VUVG / VUVS — compact universal solenoid valves with a wide range of configurations (3/2, 5/2, 5/3). Available in various sizes, for example, the VUVG (14 mm, 5/3) can deliver up to ~470 l/min, while the VUVS (26.5 mm, 5/2) can handle up to ~1000 l/min. A practical choice as a 'workhorse' for simple pneumatic functions such as cylinder control, blow-offs, grippers, etc.

VTUG — a valve terminal with multi-pin or fieldbus connection options (I-Port, IO-Link, etc.). Designed for applications requiring more than one pneumatic function, such as multi-cylinder stations. The terminal concept reduces wiring complexity and improves organization in control cabinets.

VTEM (Motion Terminal) — a digitally configurable valve terminal with piezo actuators and integrated sensors. A single physical device can perform multiple functions, from classic 2×3/2 or 4/3 logic to proportional pressure and flow control. Adjustments are made via software ('Motion Apps'), eliminating the need for mechanical modifications.

If the pneumatic line involves repetitive logic — for example, multiple cylinders with similar operating cycles — a terminal solution (VTUG or VTEM) usually pays off during the design or assembly phase. It reduces the number of connections, improves air tightness, and makes maintenance much simpler, especially for diagnostics.

These valves are designed to interrupt compressed air flow, vent the system, and ensure safe equipment maintenance or startup. They play a crucial role in both routine maintenance and compliance with occupational safety requirements.

These valves are designed to interrupt compressed air flow, vent the system, and ensure safe equipment maintenance or startup. They play a crucial role in both routine maintenance and compliance with occupational safety requirements.

HE — a manually operated 3/2 valve (on/off type) that shuts off the air supply while simultaneously venting the system. A simple and reliable solution for maintenance mode or as part of a LOTO (Lockout/Tagout) procedure.

MS-SV (soft-start / quick exhaust) — an electropneumatic valve with controlled pressure build-up and quick exhaust functions. Compliant with the highest safety standards (SIL 3, PL e) and suitable for applications requiring a safety circuit certified to EN ISO 13849 or IEC 61508. Useful for equipment startup control and preventing unintended activation.

HGL — a check valve that blocks backflow and holds the cylinder position in its normal state. When control air is supplied, the valve opens, allowing free flow. This solution is particularly useful in vertical lifting assemblies where secure load holding is required.

If equipment requires a safe maintenance mode with a venting function, the combination of HE + MS-SV is often used. HE mechanically shuts off the air supply and vents the system, while MS-SV ensures controlled pressure build-up and safe air release. This configuration facilitates LOTO compliance and enhances workplace safety.

Flow control valves regulate the flow rate of compressed air, directly influencing the speed and dynamics of actuators such as cylinders. Precise flow control ensures smooth operation, prevents end-of-motion impacts, and synchronizes different motion steps.

Flow control valves regulate the flow rate of compressed air, directly influencing the speed and dynamics of actuators such as cylinders. Precise flow control ensures smooth operation, prevents end-of-motion impacts, and synchronizes different motion steps.

GRLA / GRLZ — one-way flow controllers operating on the 'meter-out' or 'meter-in' principle. Typically installed directly on the cylinder to brake motion in one direction. These valves are essential for ensuring smooth movement, especially when precise positioning or vibration reduction is required.

Needle valves and pneumatic timers — these components are used to create delays between motion steps, synchronize actions, or impart specific dynamics, such as the so-called 'kick-down' effect (fast start, slow finish).

GRLA series valves come with datasheets featuring flow characteristic curves, which help adjust the flow for specific applications.

If a pneumatic gripper delivers a part too aggressively or 'slams' it during gripping, often a minimal adjustment of the GRLA valve on the exhaust side ('meter-out') is sufficient. This reduces impact without changes to the PLC program and improves part handling quality.

These valves are designed to maintain or limit air pressure at a specific level in the pneumatic system. Depending on the application, they can be standalone components or combined with filters to form compact and efficient modules.

These valves are designed to maintain or limit air pressure at a specific level in the pneumatic system. Depending on the application, they can be standalone components or combined with filters to form compact and efficient modules.

Pressure regulators optimize energy consumption, extend component lifespan, and improve system stability. Additionally, properly regulated pressure is essential for process repeatability and safety.

LR / LRS — standard diaphragm-type pressure regulators with two adjustment ranges: 0.5–7 bar and 0.5–12 bar. Equipped with a lockable adjustment knob and two gauge ports for flexible mounting orientation.

LFR / LFRS — combined filter-regulators that integrate air filtration and pressure regulation in one housing. Available in Mini, Midi, and Maxi sizes, as well as D-series metal housings with increased resistance to aggressive environments and corrosion.

LRP / LRPS — precision regulators with exceptionally low hysteresis and high sensitivity. Suitable for applications requiring stable and precise pressure control, such as dosing, laboratory pneumatics, or pneumatically controlled measurement processes.

A common mistake is attempting to reduce cylinder force by restricting air flow with a flow controller. While this may provide a temporary effect, it does not improve stability. The correct approach is to reduce the working pressure on the specific branch using an LR or LRS regulator. This ensures smoother cylinder movement, reduces air consumption, and lowers the risk of leaks.

This section goes beyond classic pneumatics — Festo process valves are designed for controlling various substances in different states: gases, liquids, pastes, foams, and granules. They are widely used in cooling, rinsing, CIP (Clean-in-Place), dosing, and mixing processes in the food, chemical, pharmaceutical, and other industries.

This section goes beyond classic pneumatics — Festo process valves are designed for controlling various substances in different states: gases, liquids, pastes, foams, and granules. They are widely used in cooling, rinsing, CIP (Clean-in-Place), dosing, and mixing processes in the food, chemical, pharmaceutical, and other industries.

The design of these valves is tailored to the specific properties of the media — for example, viscosity, particle content, temperature, or aggressiveness. Hygiene, cleaning, and operational parameters are also taken into account.

VZXA — an angle seat valve with pneumatic actuation and modular construction, which simplifies maintenance and configuration. Provides high flow rates, suitable for gases, liquids, and even steam. Thanks to corrosion-resistant materials and excellent cleanability, it is a popular choice for CIP systems, food, and beverage industries.

VZBM — a ball valve with 2- or 3-way functionality (L or T port). Available with manual or pneumatic DFPD quarter-turn actuators. With a wide DN and PN range, it is adaptable to various pipeline systems. Suitable for applications requiring reliable flow switching and minimal pressure loss.

VZQA — a so-called ‘pinch’ valve, where the flow channel is formed by a flexible tube that is pneumatically pinched or released. Ideal for abrasive, particle-laden, or viscous media — such as granule suspensions, food mixtures, or pharmaceutical solutions. Available in both NC (normally closed) and NO (normally open) versions. Advantage — the tube is easy to replace and clean.

VYKA — media-separated solenoid valve, where the fluid is not in direct contact with the electromechanical components. This diaphragm separation ensures high chemical resistance and suitability for aggressive or sterilizable media. Ideal for laboratories, analytical equipment or precise microdosing, where very small flow control is required (available in 2/2 and 3/2 configurations).

If the system needs to handle liquid with solid particles — for example, sugar syrup with crystals or granule suspensions, conventional valves often clog or wear out. In such cases, the ideal solution is the VZQA pinch valve, as the flow is sealed by an elastic tube, which does not restrict particle flow and is easy to replace.

Meanwhile, in CIP (Clean-in-Place) cleaning processes, where hot water, steam, or cleaning solutions flow, the VZXA series valves are often preferred. They withstand high temperatures, provide high flow rates, and are designed to meet hygiene standards.

| Control | Application | Festo examples |

|---|---|---|

| Manual / mechanical | HMI, initial setup, safe intervention, simple logic | VHEF – offers various activation options (push button, switch, lever), available in 3/2, 5/2, 5/3 configurations; VMEF – mechanical valves with stem, roller lever, etc. |

| Electronic (solenoids, terminals) | PLC control, high cyclic load, diagnostics | VUVG/VUVS, VTUG, VTEM (Motion Terminal) |

| Pneumatic (piloting) | Decentralized logic nodes, position holding, process valve actuation | HGL (pilot-operated check valve), process valves with pneumatic actuators (e.g., VZXA, VZBM) |

| Function | Series | Features |

|---|---|---|

| Directional control | VUVG, VUVS | 3/2, 5/2, 5/3; compact; flow rate up to ~1000 l/min |

| Directional control for terminals | VTUG, VTEM | VTUG – multi-pin / fieldbus; VTEM – piezo actuators, “Motion Apps,” proportional functions |

| Shut-off / Safety | HE, MS-SV, HGL | HE – manual shut-off and venting; MS-SV – SIL3 / PL e; HGL – check valve holds cylinder |

| Flow control | GRLA / GRLZ | “Meter-in/out,” cylinder cushioning, flow curve available |

| Pressure regulation | LR / LRS, LFR / LFRS, LRP / LRPS | Various pressure ranges; filter regulators; precision models with low hysteresis |

| Process valves | VZXA, VZBM, VZQA, VYKA | Angle seat, diaphragm, pinch, and ball valves; suitable for liquids, gases, granules, and CIP |

To select the right valve, thread diameter or mounting type alone is not enough. It is important to understand the valve's function, operating mode, and the process substances that will flow through the system. Below are practical criteria and their significance in real-world operation.

3/2 — suitable for single-acting cylinders; allows air supply for extension and exhaust for retraction (via spring or other mechanical force).

5/2 — full control of double-acting cylinders.

5/3 — provides a neutral middle position (closed, pressure-balanced, or exhaust), important for safety scenarios.

VTEM (Motion Terminal) allows these functions to be configured at the software level — without physical changes.

Manual — convenient during commissioning/testing and maintenance.

Electric (solenoids, IO-Link, bus networks) — enables fast operation, feedback, and diagnostics.

Pneumatically piloted valves (air-piloted valves) — ideal for decentralized logic, local control points where electrical wiring is limited, or situations requiring non-electric position holding.

Ensure the valve's flow rate (Qn) and pressure range meets the system requirements (see the respective series datasheets — VUVG, GRLA, etc.). Insufficient flow may slow down and destabilize cylinder operation Eltra Trade.

Typical error: when trying to reduce cylinder force by restricting flow with GRLA — this causes uneven movements. It is necessary to reduce working pressure with a regulator (LR/LRS), which ensures smooth operation and efficiency.

It is important to select a valve based on the process medium:

| Medium / conditions | Recommended Festo valve |

|---|---|

| Abrasive, solid particles | VZQA (pinch valve) |

| High flow rate / high temperature | VZXA (angle seat valve) |

| Chemical / sterilizable liquids | VYKA (media-separated solenoid) |

If the system requires a safety function — for example, venting or preventing unexpected starts — certified valves must be selected:

MS-SV — combines soft-start and quick exhaust functions, complies with SIL 3 / PL e, suitable for systems meeting relevant safety standards (EN ISO 13849-1, IEC 61508) Festo.

Previously, each of the 8 cylinders in the production line had a separate VUVG valve. Switching to a VTUG valve terminal significantly reduced the number of threads and pipes, simplified wiring, and made spare parts management easier — one valve type was sufficient for the entire system.

These improvements reduce complexity, increase reliability, and standardize spare parts.

The company regularly changes product formats and wants to adjust cylinder operation — speed, force, and “soft-stop.” With the VTEM Motion Terminal, these functions can be configured via software (“Motion Apps”) without replacing mechanical components or installing additional valves. This allows quick adaptation of production to different tasks.

Flow control on the supply side

Adjusting air supply (“meter-in”) often causes unstable cylinder movement. The correct practice is to brake movement on the exhaust side with a GRLA regulator at the cylinder (“meter-out”).

Pressure reduction with a flow valve

This does not affect cylinder force. To reduce working force, a pressure regulator (LR / LRS) should be used instead of a flow valve.

Ignoring safety requirements

If the equipment needs to meet SIL or PL standards, certified valves like MS-SV must be used instead of standard 3/2 vent valves.

Selecting a process valve unsuitable for the controlled medium

Selection should be based on the properties of the medium and temperature:

| Requirement | Recommendation |

|---|---|

| Universal directional control for cylinders | VUVG/VUVS solenoid valves |

| Multiple valves in one assembly | VTUG valve terminal (multi-pin/fieldbus, IO-Link) |

| Flexible function changes and sensor integration | VTEM with Motion Apps (direction, pressure, flow, Soft Stop) |

| Safe shutdown, venting, and startup (LOTO) | HE + MS-SV (SIL 3 / PL e) |

| Cylinder speed control | GRLA/GRLZ (meter-out / meter-in) at the cylinder |

| Constant pressure in a specific branch | LR/LRS or LFR/LFRS (filter + regulator) |

| Process media (liquids / gases / granules) | VZXA, VZBM, VZQA, VYKA — selection based on medium properties and temperature |

Valves are a “silent” but critical part of the production chain — they directly affect safety, quality, and overall operating costs. If you need help selecting a directional, flow, pressure, or process valve, contact us — we will help you find the right solution and compatible accessories.