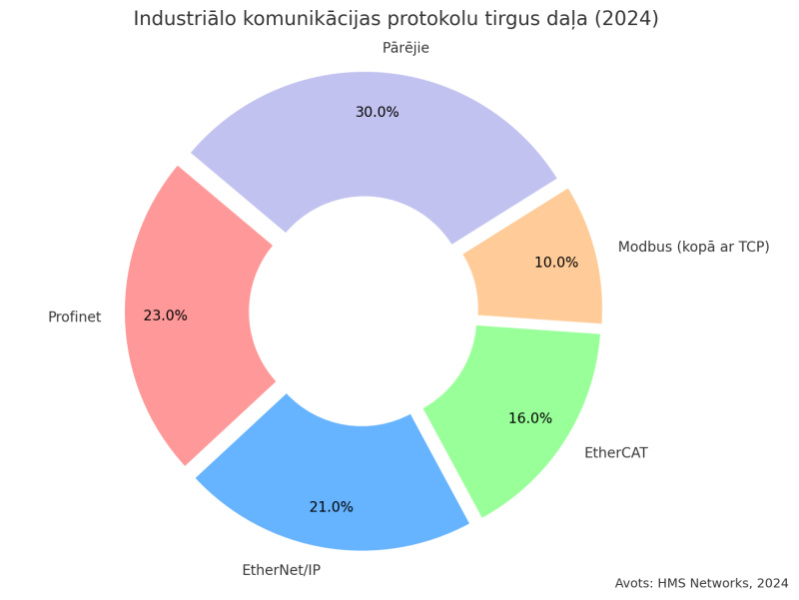

Do you know which Ethernet protocol had the largest market share in 2024? It's Profinet – with a 23% share, it dominates the industrial networking sector (source: HMS Networks, 2024). Weintek has also implemented and now supports Profinet IO Master functionality in its CODESYS SoftPLC solution.

Profinet (Process Field Network) is an open, Ethernet-based industrial protocol that enables real-time communication between devices within an industrial network. It is maintained by the organization PROFIBUS & PROFINET International (PI).

Combines high data transmission speed with determinism. This ensures data is transferred quickly and with precise timing – crucial for high-speed or complex production lines.

Compatibility with other Ethernet protocols (e.g., HTTP, MQTT). This allows different systems to operate within a single network without added complexity.

Integration of PROFIBUS devices. This enables the use of existing equipment alongside newer technologies, ensuring a smooth transition to modern systems. (source: Automation.com)

With the latest update, the Weintek CODESYS SoftPLC platform now supports Profinet IO Master functionality. This means:

By installing the CODESYS SoftPLC software on a cMT X series HMI, users gain both visualization capabilities and full PLC control functionality. This integrated control and visualization in a single device simplifies project architecture, reduces costs, and saves space in control cabinets. Additionally, this solution enables faster configuration and maintenance and improves data throughput between logic and visualization layers.

By installing the CODESYS SoftPLC software on a cMT X series HMI, users gain both visualization capabilities and full PLC control functionality. This integrated control and visualization in a single device simplifies project architecture, reduces costs, and saves space in control cabinets. Additionally, this solution enables faster configuration and maintenance and improves data throughput between logic and visualization layers.

Today’s industrial environment demands solutions that ensure efficiency, compatibility, and sustainable growth. However, automation systems must also be:

Weintek CODESYS SoftPLC with Profinet IO Master functionality provides a solution that meets all these requirements:

Weintek CODESYS SoftPLC with Profinet IO Master functionality provides a solution that meets all these requirements:

This table summarizes the most commonly used industrial automation communication protocols, their key features, and typical applications.

| Protocol | Key Features | Application / Description |

|---|---|---|

| Profinet | Real-time, deterministic, open | Ideal for high-speed machines, widely used in Europe |

| EtherNet/IP | Based on CIP, Ethernet compatible | Popular in the US, supports both time-critical and regular data exchange |

| EtherCAT | Low latency, deterministic | Suited for precise control – robotics, motion control |

| Modbus / Modbus TCP | Simple, open | Commonly used with sensors, PLCs, and legacy systems |

| OPC UA | Platform-independent, secure | For IoT and Industry 4.0 integration |

| PROFIBUS | Fieldbus protocol | Still widely used in legacy systems |

| CANopen / DeviceNet | Based on CAN, efficient | For real-time control and embedded systems |

| HART | Analog + digital communication | Used for sensor and transmitter control in process automation |

| CC-Link | Deterministic, fast | Very popular in Asia, especially Japan |

Sources: HMS Networks, MaisVCH