Telemecanique Sensors IO-Link: Smarter Automation for Faster and More Efficient Manufacturing

December 10, 2024

Did you know that industrial automation is rapidly advancing thanks to technologies that enable machines to communicate smarter and faster? IO-Link technology has become one of the essential tools, providing bidirectional communication between sensors and automation systems. Telemecanique Sensors, a leading provider of this technology, offers solutions that not only simplify system integration but also help businesses reduce costs and improve efficiency. In this article, we will explore the advantages of IO-Link and how Telemecanique Sensors’ offerings can radically enhance your manufacturing process.

What is IO-Link technology?

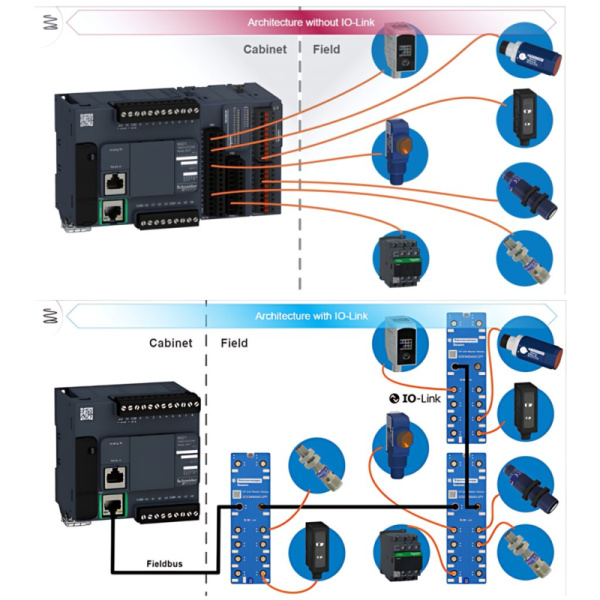

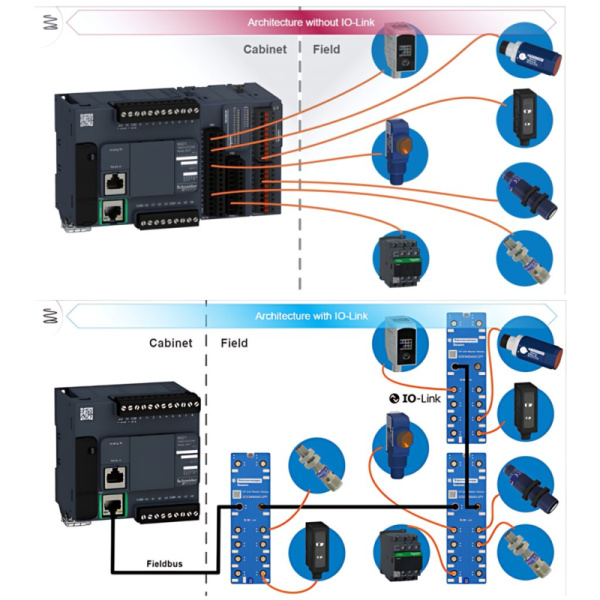

IO-Link is a standardized communication protocol that enables intelligent communication between sensors and controllers. It is a vital part of Industry 4.0 and smart manufacturing, allowing real-time data exchange, problem diagnosis, and automatic parameter setting.

Key features of IO-Link technology:

- Bidirectional data exchange: Sensors and controllers can exchange data, ensuring efficient communication between production components.

- Simple installation: Uses standard cables, significantly reducing costs, simplifying the installation process, and eliminating the need for complex wiring connections.

- Enhanced diagnostics: Continuous monitoring of devices and sensors allows timely detection of issues, reducing downtime and maintenance costs.

Key Benefits of IO-Link Technology

1. Cost Reduction

- Standard 3- or 4-wire cables are up to 10 times cheaper than analog alternatives, allowing significant cost savings.

- Simplified architecture and fewer sensor types reduce installation and maintenance costs by 25–30%, making the system more efficient and easier to manage.

2. Improved Efficiency

- Real-time data analysis identifies processes that need optimization, improving product quality and reducing defects.

- Sensor monitoring and quick replacement significantly enhance production equipment uptime, minimizing unplanned downtimes.

3. Faster Implementation

- Standard cables and quick configuration significantly reduce system implementation time, ensuring companies can adopt new technologies faster, saving up to two weeks.

- Built-in configuration tools enable fast and error-free system integration, optimizing the implementation process.

4. Enhanced Flexibility

- Automatic parameter setting allows easy adaptation to changing production requirements, improving system flexibility and adaptability.

- Modular design and standardized IO-Link architecture provide simple system expansion and adaptation for future needs.

Telemecanique's IO-Link Master Solutions

Telemecanique Sensors offers two excellent IO-Link Master solutions:

- XZIOM8AM12EY: Suitable for Ethernet/IP networks.

- XZIOM8AM12PY: Optimized for Profinet networks.

Key Features:

- IP67 protection class: Ensures durability in challenging industrial environments.

- 8 configurable Class A ports: Adaptable to various production scenarios.

- Wide operating temperature range: From -20°C to 70°C.

These solutions provide easy integration with various PLCs and cloud technologies using OPC UA and MQTT protocols, enabling fast and accurate access to sensor data.

Practical Benefits of IO-Link Solutions in Industry

Real-World Applications

In a medium-sized plant with 50 IO-Link devices, costs can be reduced by up to 40% compared to traditional solutions such as PROFINET or EtherNet/IP.

Problem Diagnosis

With continuous data exchange, companies can perform proactive maintenance, significantly reducing downtime and maintenance costs.

Improved Quality

Real-time analysis and data availability help optimize processes and improve the quality of the final product.

IO-Link technology is essential for Industry 4.0 implementation, enabling intelligent communication and increasing production efficiency. These solutions help businesses simplify process automation, reduce costs, and improve competitiveness.

If you’re ready to optimize costs, improve efficiency, and implement modern automation solutions, contact our experts – we’ll help you find the best solution!