Did you know that nearly 40% of industrial motor failures are caused by overloads and short circuits? Your operation's lifespan and efficiency depend on protecting your electro motor.

Industrial automation requires motor protection to maintain motor longevity, reliability, and efficiency. Robust and sophisticated motor protection systems are needed more than ever in complicated industrial situations. Understand and implement motor protection to save time and money and avoid unplanned downtimes.

In the following article, we'll cover motor protection's need, the different sorts of devices, and how to choose the ideal one for your needs. This article will help you improve your motor's performance and properly maintain your investments.

Industrial motors are the workhorses of countless industries, driving essential machinery and processes. However, these vital components are vulnerable to a range of potential issues, including:

According to industry data, most motor failures are preventable with proper protection mechanisms in place.

There are many different types of motor protection, and each one is designed to meet a different set of operational requirements and potential dangers. This is an overview of the most common types:

Thermal overload relays protect motors from overheating due to sustained overload conditions. These relays measure the temperature of the motor windings and disconnect the motor if the temperature exceeds safe limits. This type of protection is ideal for environments where motors are subject to frequent start/stop cycles, which can generate excessive heat.

Thermal overload relays protect motors from overheating due to sustained overload conditions. These relays measure the temperature of the motor windings and disconnect the motor if the temperature exceeds safe limits. This type of protection is ideal for environments where motors are subject to frequent start/stop cycles, which can generate excessive heat.

Schneider Electric GV2ME08 Circuit Breaker is designed for motors with a power rating of 1.5 kW, offering reliable thermal protection with a current range of 2.5A to 4A.

Schrack Technik BE504000 Circuit Breaker provides similar protection for motors up to 1.5 kW, with a current range of 2.5A to 4A, ensuring operational safety and reliability.

Magnetic circuit breakers and relays provide rapid response to short circuits by instantly disconnecting the power supply, preventing significant damage. This protection is crucial in environments where power surges are common.

Magnetic circuit breakers and relays provide rapid response to short circuits by instantly disconnecting the power supply, preventing significant damage. This protection is crucial in environments where power surges are common.

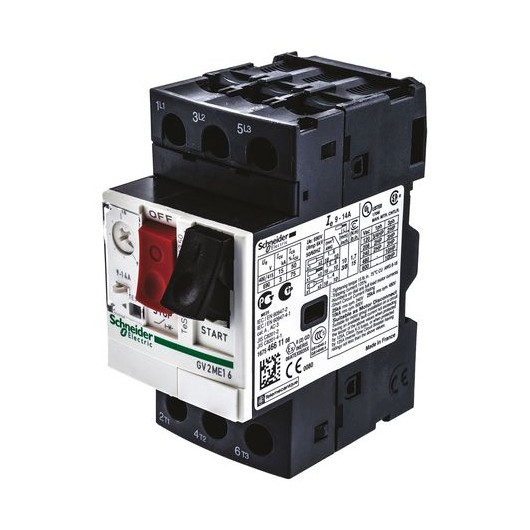

Schneider Electric GV2ME16 Circuit Breaker is suitable for motors up to 5.5 kW, offering combined thermal and magnetic protection with a current range of 9A to 14A.

Schrack Technik BE510000 Circuit Breaker also serves motors up to 4 kW, providing robust thermal-magnetic protection with a current range of 6.3A to 10A.

Advanced electronic relays and breakers offer programmable settings, allowing for precise control over various protection parameters, including overload, phase imbalance, and short circuit conditions. These devices often include diagnostics and communication features, making them ideal for integration into modern, automated systems.

Advanced electronic relays and breakers offer programmable settings, allowing for precise control over various protection parameters, including overload, phase imbalance, and short circuit conditions. These devices often include diagnostics and communication features, making them ideal for integration into modern, automated systems.

Schneider Electric LT4760M7S Electronic Overload Relay supports a wide current range from 5A to 60A, offering advanced protection features for industrial applications.

Schrack Technik LSTD1200 Electronic Overload Relay provides reliable protection for motors with a current range of 9A to 12A, ensuring optimal performance and longevity.

These systems go beyond simple protection, integrating control, monitoring, and predictive maintenance capabilities. They can communicate with other systems, providing valuable data for optimizing motor performance and preventing failures before they occur.

Schneider Electric TeSys T Motor Management System offers comprehensive motor protection, monitoring, and control, suitable for high-end applications where downtime is not an option.

Schrack Technik Motor Management System offers similar advanced features, ensuring reliable operation and integration into existing industrial control systems.

Selecting the right motor protection device depends on several factors, including the motor’s power rating, the operational environment, and the specific risks involved. Here are some steps to guide your decision:

Motor protection is not just a safeguard—it’s an investment in the reliability and efficiency of your operations. By selecting the right protection devices, you can significantly extend the lifespan of your motors, reduce downtime, and optimize performance.

Whether you’re dealing with a small, single-phase motor or a complex multi-motor setup, the right protection strategy can make all the difference. Schedule a consultation today to ensure your motors' safety. Let's customize a solution to match your demands and streamline processes.

Contact our specialists to discuss your motor protection needs.

We're here to protect your motors and optimize your operations.